Electrical Assembly Services You Can Trust

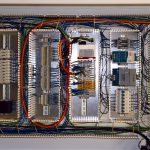

Electrical assembly is a process required for most products built at PEKO. To effectively respond to these needs, we provide electrical assembly services that support the low volume high mix requirements for a range of electromechanical products varying in size, shape, function, industry, and robustness. Whether you need I/O wiring, signal conditioning, board interconnections, chassis wiring, or other electrical assembly services, look no further than PEKO. We have the knowledge and tools to get the job done right.

Unleash the Power of a Full-Service Electrical Assembly Manufacturing Partner

We have experience integrating electrical connections into thousands of products and have worked with most electrical components common to industrial machinery and equipment. Using electrical assembly best practices, our electricians can assemble, mount, wire, and connect a variety of electrical components and assemblies per customer specifications and applicable codes/standards.

- Electrical Know-How: When it comes to electromechanical products, we can assist with most aspects of electrical assembly. We work with wire harnesses, cable assemblies, switches, relays, sensors, motors, industrial power supplies, transformers, din rails, actuators, and more.

- Fabrication & Integration: We have in-house resources to fabricate the enclosures, cabinets, chassis, and other structural assemblies needed to house electrical assemblies and components. We also provide complex systems integration for customers who desire a more turnkey solution.

- Engineering & Prototyping: When a build requires further support before production can begin, we have a highly skilled team of NPI engineers to help specify and configure the right technologies and components for your build and handle panel wiring, field wiring, and pneumatic plumbing on prototype builds.

- Documentation & Scaling Up: Our team of electricians work closely with our engineering and production teams to develop all manufacturing documentation, including work instructions, wiring diagrams, and matrices that are needed to properly support all programs as they scale up to full production volumes.

- Supply Chain Management: Our supply chain management activities include sourcing and procurement to ensure COTS and custom electronics arrive at the assembly area on time.

- Testing & Compliance: All electrical assembly work is completed in house to ISO standards. We provide custom testing of individual assemblies to ensure they function as intended and conform to electrical safety requirements, including UL and IP-620, among others. We also maintain several areas to implement electronic static discharge (ESD) protection and control measures, as per spec.

- Application Experience: Our electricians can work with many applications, including industrial box builds, control cabinets, electrical control assemblies, motor assemblies, busbar assemblies, back panels, sub-panels, racking systems, radar subsystems, communications consoles, and more.

Electrical Wiring & Assembling That Delivers The Highest Quality Results

We have highly skilled electrical staff on-site who are qualified to perform a range of activities involved in the assembly and wiring of electromechanical equipment, and we are constantly making improvements to expand this offering. Specifically, our electrical assembly capabilities include:

- Understanding and interpreting electrical schematics and wiring diagrams.

- Determining electrical component parts and assembly sequences per blueprints.

- Developing work instructions, wiring diagrams, and matrices for early-stage builds.

- Sourcing and procuring appropriate electrical/electronic components and machine controls.

- Manufacturing of custom wire harnesses and cable assemblies with automated processes.

- Preparing wires and cables for installation using cutting, stripping, and crimping methods.

- Laying out, positioning, and integrating electrical components and wiring into back panels.

- Managing and routing electrical wires through frame construction, from back panels to sensors.

- Point-to-point wiring from connection points in the panel to corresponding devices in the machine.

- Soldering and brazing joints, where specified, to create strong, reliable electrical connections.

- Implementing electronic static discharge (ESD) protection and control measures, as per spec.

- Troubleshooting, debugging, and modifying electrical assemblies and subsystems when needed.

- Inspecting and testing completed units to verify conformity of customer/industry requirements.

- Connecting HMIs, sensors, and various other electrical controls technologies into assemblies.

At PEKO, we can install and interwire an array of electronics, electrical components, and subassemblies to ensure consistent performance of your machinery or equipment. So, when you’re in need of an electrical assembly provider, you can trust that PEKO has the skills, experience, and resources to get the job done right, from PLCs and drives to sensors and controls and everything in between.