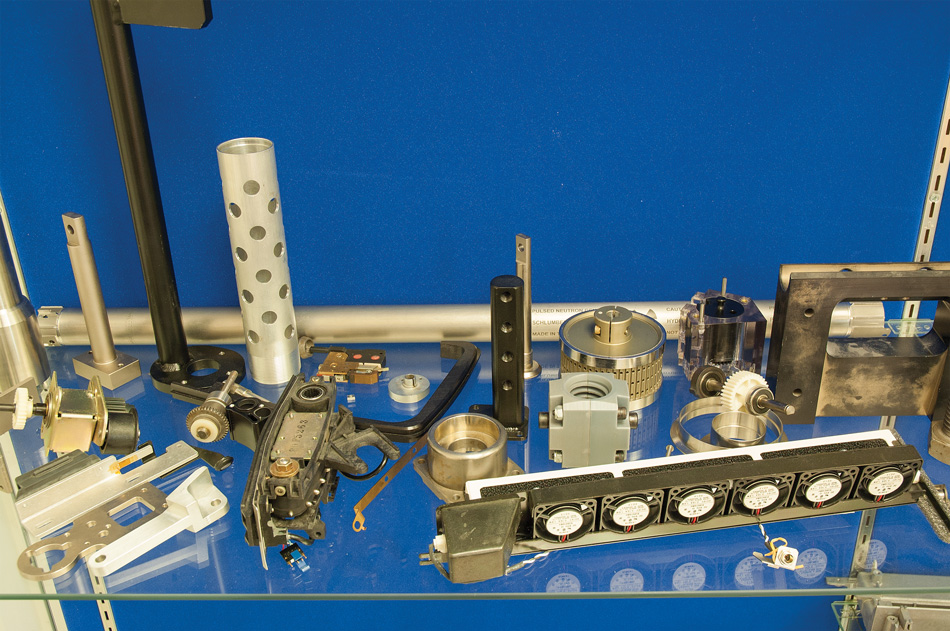

Small Parts CNC Machining – Milling and Turning

PEKO’s produces CNC machining small parts for a wide variety of industries and applications. At our Rochester, NY facility, there are 25 CNC machines dedicated to our small parts services. These machines carry work envelopes of under 25 inches and are supported by an inspection/quality group with the latest in metrology technology. Semiconductor, defense, medical, and communication industries rely on our skilled CNC machine operators abide by the latest quality standards. Of course, our small parts CNC machining can be upgraded into precision mechanical assemblies or used in machinery manufacturing.

Machinery for CNC Machining Small Parts

PEKO’s fleet of CNC machines for small parts spans across assets. Moreover, our fleet of CNC machines in this category has a wide range of machine types:

- Horizontal CNC Machines

- Vertical CNC Machines

- CNC Turning Centers

- High Speed Spindles

- High Torque Spindles

- Pallet Changers

- Wire EDM

Applications and Products

Small CNC machined parts can be found in just about every hardware product in Contract Manufacturing. Machinery and equipment are comprised of dozens of these parts. We specialize in aluminum, stainless steel, carbon steel and other common materials. For exotics, PEKO can review your application and assess. For example, here are some common applications for small CNC machining parts:

- Brackets

- Adapters

- Knobs

- Plates

- Spacers

- heat sinks

- Standoffs

- Bushings

- Levers

- Cranks

- Shafts

Properly machining small CNC parts requires high quality machinery and talented personnel. Also, a solid foundation of QA and QC helps to ensure the right parts are going out the door at the right time.

PEKO is constantly improving our machining department as we continue to expand and reinvest into our organization. For the most up to date information on our machine shop capabilities, please visit our Facilities Page.