Almost every successful product launch starts with a prototype. This functioning model often serves as the “moment of truth” that enables you to see your concept as a real, tangible product.

Unfortunately, many businesses with great ideas don’t have the ability to build working prototypes. Some may even lack the ability to move from concept to design. In these cases, a prototype development company can be the answer.

“Every great idea starts somewhere. Our goal is to leverage PEKO’s 50 years of experience in the industry and world-class resources to serve as a toolbox to take a concept to new product development success,” explained PEKO’s Sales and Marketing Manager, Scott Baxter.

What do prototype development companies do?

Here are five critical ways a prototype development company can help you in the product development process.

- Nurture Your Idea: At this point, your idea is at its broadest point, and that can make it challenging to establish the critical details needed for the product’s development. Your concept could literally exist anywhere: inside your head, on the back of a cocktail napkin, or in a 3D model. Building a prototype can help you gain clarity, according to Entrepreneur.com. A prototype development company’s design team can help you explore your idea before building your first prototype. This is particularly important when you don’t have a clear vision of how the product will function or what the end product is going to look like. For example, they can help you evaluate different concepts to ensure that you have accounted for all facets of your project, like internal components, color, size, and more. Think of it as fine-tuning your idea so that you can create your prototype project with clear definitions, milestones, and final goals.

- Refine Your Initial Concept: Once you have a manageable scope for your product, a prototype development company can then help you prove your design concept has merit and is functional. During this stage, the company will help you verify your science and technology, define critical parameters, and perform initial testing to establish specifications and requirements. It may also help you identify solutions to address any challenges that you may encounter with the product. For example, you may want a lower-cost product, so you will need to consider parts that can be purchased off the shelf instead of custom-made. Through this process, refinement of your initial concept will often happen – which is essential to reducing design iterations and “surprises” in future stages.

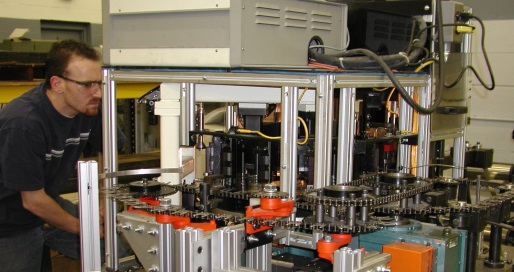

- Build a Working Model: After proving the functionality of your design and generating specifications, it’s time to turn your concept into reality by physically producing the product. A prototype development company should have a full range of resources available to build a functional prototype. In some cases, like if you need rapid prototyping in a matter of days, this may just mean a 3D printer mockup, but if you’re looking for a manufactured working model, the prototype development company will need to leverage resources like production tooling, CNC machines, electrical shop, certifications and more to fabricate your prototype. In this phase, however, the company will be focused on manufacturing an early-stage product to prove your concept rather than mass production, so you won’t have a piece intended for a long shelf-life. And keep in mind that this stage can often require iterative loops of execution before reaching success. The ultimate objective of a prototype is to help you identify if your product design works as expected so you can demonstrate your idea to your stakeholders.

- Work out the Kinks: Once you have a model manufactured, you’ll realize that you didn’t arrive at that point without some mistakes along the way, especially since there was no pre-established process for fabricating your prototype. This is when you may also want to lean on your prototype development company to apply any lessons learned from the manufacturing process to improve your product’s performance and functionality. At this point, the company will bring in test engineering, quality management systems, and compliance to review your project. Then it will help you work out the final manufacturing details so that when you’re ready to ramp up production volume, you don’t discover any flaws or issues, allowing you to streamline mass production. Think of this stage as the final dress rehearsal prior to production-level release.

- Ready You for Prime Time: Are you just looking to develop the intellectual property to sell or do you want to manufacture the product? Depending on what you want from your prototype, you may want to tap into the manufacturing company’s resources and your relationship with them for the first production build of your prototype. When you’re at this phase, the design is essentially “frozen,” the drawings formally released, and configuration control implemented. Quality systems are also in place and any final testing and regulatory requirements are approved. The idea is that your first batch that comes off the production line should be the product you envisioned and prototyped. Depending on additional services you may need, the prototype development company may also be able to assist you with services to get your product to market, like logistics and packaging.

Just like every product idea is different, so too is the prototype development process for each invention. But by collaborating closely with a prototype development company, you’ll be able to take your idea from the drawing board to a finished product, one that’s the best it can be. And that can often mean the difference between the failure and success of your business.

Just like every product idea is different, so too is the prototype development process for each invention. But by collaborating closely with a prototype development company, you’ll be able to take your idea from the drawing board to a finished product, one that’s the best it can be. And that can often mean the difference between the failure and success of your business.

Looking for a prototype development company to help with your project? Download our checklist to help you find the ideal partner for your prototyping needs.