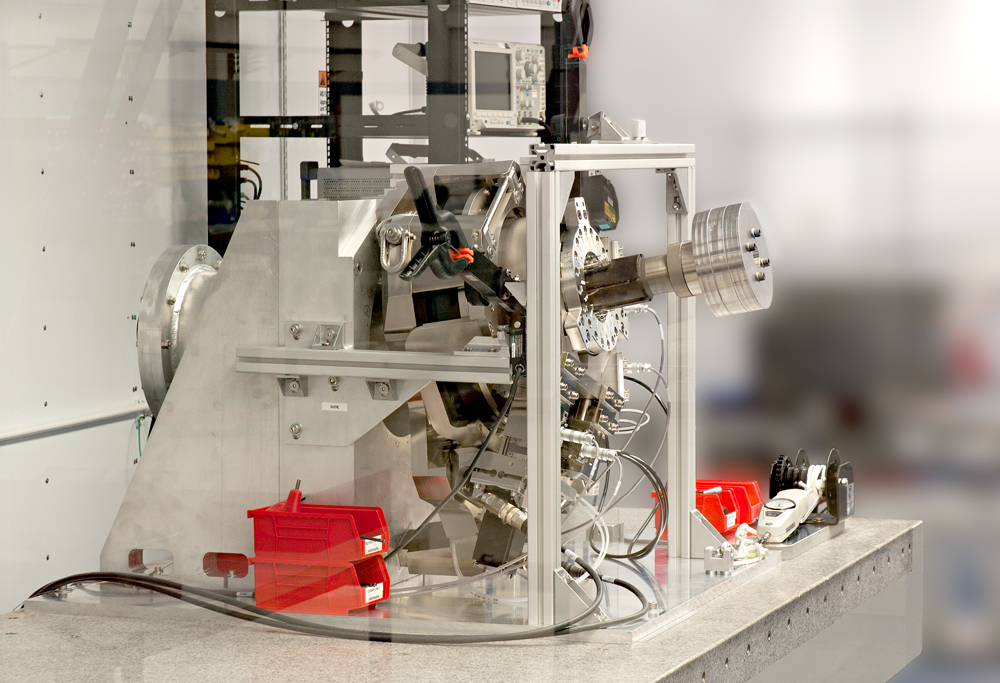

Precision Built Sub Assemblies for Complex OEM Products

Looking for a dependable partner to handle your sub-assembly manufacturing needs? PEKO specializes in building complex subassemblies that integrate seamlessly into your higher-level systems. Whether you’re preparing for full-system integration or looking to offload non-core assembly tasks, we deliver precision, scalability, and accountability—so your teams can focus on what matters most.

Your Full-Service Sub Assembly Manufacturer

PEKO’s vertically integrated capabilities allow us to build highly complex subassemblies with precision, consistency, and efficiency—all under one roof. From design support and sourcing to fabrication, testing, and delivery, our sub-assembly services are built to meet the needs of today’s high-tech, fast-moving OEMs.

Why OEMs Trust PEKO:

- Low-to-medium volume subassembly manufacturing optimized for precision and scalability

- Mechanical, electrical & electromechanical sub-assemblies expertly built under one roof

- Seamless integration of metal components, electrical systems, and structural enclosures

- ISO 9001:2015, AS9100D, IPC-A-610/620, and ISO 13485:2016 certifications

- Trusted by high-tech OEMs across medical, defense, and industrial automation sectors

What Is Sub Assembly Manufacturing?

Sub-assembly manufacturing is the process of assembling components into smaller modules or units, ready for integration within a larger, more complex final product assembly. These units—often called subassemblies or sub-assemblies—can include:

- Precision machined & sheet metal fabricated parts

- Custom electrical wiring and cable assemblies

- Integrated sheet metal enclosures and frames

- Electromechanical systems with moving parts

Our Proven Sub Assembly Manufacturing Process

- Design Review & Engineering → We start by reviewing your BOMs, 3D models, and drawings, to identify DFM opportunities. Our engineers work with your team to streamline part count, reduce complexity, lower production costs, and improve manufacturability and assembly repeatability.

- Strategic Sourcing & Procurement → Our supply chain team sources and procures electronics, subcomponents, and raw materials from our vetted supplier network. We manage inventory planning, just-in-time material delivery, and risk mitigation strategies across the supply chain.

- Fabrication & Sub Assembly → With in-house capabilities for CNC machining, sheet metal fabrication, welding, painting, and wiring, we build each sub-assembly to exact specifications. Our skilled technicians adhere to controlled processes, ensuring consistency and precision in every unit.

- Complete Testing & Quality Control → Every sub-assembly undergoes thorough inspections and tests to verify functionality and performance. Our quality control processes guarantee that each unit meets the highest standards of fit, form, and function before being delivered.

- Kitting, Packaging, & Delivery → We package your sub-assemblies according to your specs—labeled, kitted, and delivered just-in-time for your production schedule. We also offer high-level assembly or system integration on-site as part of our turnkey contract manufacturing solutions.

Industries We Support

PEKO’s flexibility and expertise make us the go-to subassembly provider for highly regulated and complex industries. Our team understands the unique compliance and engineering challenges faced by:

- Medical & Life Sciences → Clean, high-precision subassemblies for laboratory equipment, diagnostic instruments, and analytical devices

- Aerospace & Defense → Mechanical and electromechanical subassembly manufacturing for mission-critical applications and platforms

- Industrial Automation & Robotics → Custom fabricated frames, motion systems, and enclosures for automated manufacturing systems

- Renewable Energy & Semiconductor → Complex assemblies for power distribution, semiconductor fabrication, and sensitive builds

Benefits of Our Sub Assembly Services

At PEKO, we offer more than traditional sub-assembly services — we combine the expertise of a seasoned contract manufacturer with the precision of a systems integrator. While many vendors simply build to print, we take a proactive approach by collaborating with you to engineer solutions, uncover inefficiencies, and deliver strategic insights that enhance your results.

Partnering with PEKO means you can:

- Lighten your internal workload and reallocate valuable resources to core priorities

- Enhance build quality with greater consistency and repeatability across complex assemblies

- Accelerate your time-to-market with a dependable, single-source manufacturing partner

- Minimize supply chain risks by reducing reliance on multiple vendors

- Leverage engineering expertise to drive design improvements and cost savings

Let’s Build Together

If your team is seeking a dependable, experienced partner for sub-assembly manufacturing, PEKO offers the tools, talent, and technology to deliver real value. We handle the complexity, so you can focus on innovation and growth.

Contact us today to learn more about how our sub-assembly services can support your next project.