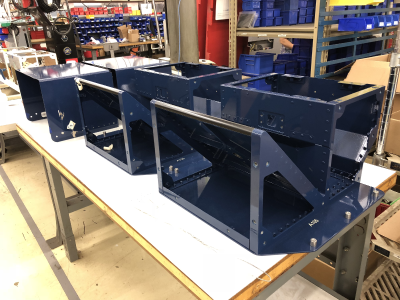

The industrial wet painting services offered at PEKO are performed in two industrial wet paint booths within our sheet metal fabrication division. Our operators are painting components prior to final integration, whether that be here at PEKO or at the customer assembly line. Wet spray painting is great for applications that would be adversely affected by the heat of powder coating, require a thin finish, or are too large for a powder coat oven. With our immense paint booth size, PEKO provides industrial wet paint services for products of all sizes and shapes. Typically, the parts are for use in high-tech industries like defense (CARC paint), semiconductor, 5G communications, and industrial applications.

In-House Industrial Wet Painting

- High-capacity wet paint booths (2)

- Large industrial drying ovens (2)

- Accommodates large sizes up to 10′ x 14′

- Self-contained to reduce FOD (foreign objects and debris)

- Two-part paint systems

- Primer and topcoat

- Standard and custom paint colors

- CARC wet painting

- All major paint suppliers supported

- Part masking

- Metal silk screen printing

- Fully-automated powder coating

Common Wet Paint Product Applications

- Frames

- Enclosures

- Structures

- Beams

- Chassis

- Covers

- Skins

- Sheet Metal Parts

- CNC Machined Parts

- Control Cabinets

- Control Panels

- And More

PEKO’s paint department has provided customers with peace of mind for assembly applications. By choosing PEKO’s industrial wet painting services to build your major assemblies and equipment, you will save money and aggravation by using a trusted paint source rather than an outside vendor. For the most up-to-date information on our painting capabilities, please visit our Facilities Page.