Advanced Sheet Metal Assembly for Complex Fabricated Systems

Looking for high-quality sheet metal assembly services? PEKO delivers expertly engineered custom fabricated sheet metal assemblies for OEMs building critical equipment. From standalone brackets to fully integrated electromechanical systems, we specialize in sheet metal assembly and integration for complex, high-performance applications.

Why Choose PEKO for Sheet Metal Assembly?

Whether you need a few dozen parts joined into a subassembly or hundreds integrated into a complete system, PEKO’s team is built for the challenge. Our sheet metal assembly services are tailored for low-to-medium volume production, with dedicated work cells and a hands-on approach that ensures precision, quality, and consistency.

Trusted for Complex, High-Value Assemblies

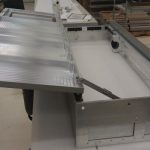

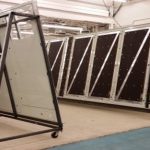

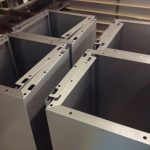

At PEKO, we don’t just build frames—we provide complete sheet metal assembly solutions engineered to meet the most demanding requirements of capital equipment OEMs. We specialize in multi-component assemblies critical to the function and integrity of complex, high-value equipment, often requiring precision alignment, wiring paths, grounding considerations, and structural support.

Program-Driven Quality & Repeatability

Quality isn’t just a goal—it’s built into every step of our process. For each assembly program, we develop repeatable processes that include complete documentation, controlled inspection protocols, standardized work instructions, and purpose-built tooling and fixtures. This approach ensures every unit—whether prototype or production run—is built with consistent quality, accuracy, and efficiency.

Complete In-House Control for Superior Quality

With most sheet metal parts fabricated, finished, and inspected in-house, we maintain complete control over part quality before anything reaches the assembly floor. This integrated capability eliminates delays and variability associated with third-party suppliers, enables real-time quality assurance and traceability, improves responsiveness to engineering changes, and shortens lead time.

Scalable Facilities from Prototype to Production

With over 200,000 ft2 of dedicated assembly space across four specialized facilities, PEKO is equipped to handle jobs of all sizes. Our facilities include overhead jib cranes and ergonomic lift-devices, dedicated cleanroom spaces, and customized assembly work cells. Whether you need a handful of prototypes or low-volume production, we have the capacity and infrastructure to deliver.

Turnkey Electromechanical & Value-Added Services

PEKO’s capabilities go far beyond sheet metal assembly with a full suite of value-added services to transform assemblies into complete units ready for installation, shipment, or final delivery. We can provide CNC machining, electromechanical assembly, cleanroom assembly, functional testing, and even full system integration. We also source and procure all required COTS and electronic components.

Engineering Collaboration & DFMA Assistance

Working with PEKO means you don’t have to settle for subpar sheet metal assembly that cost you time and money. Our partnership goes beyond manufacturing—we serve as an extension of your engineering team, offering actionable insights to help improve your design, solving complex manufacturability challenges and ensuring high-quality, cost-effective assemblies processes.

Sheet Metal Assembly Process at PEKO

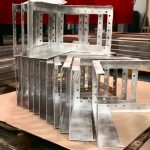

- Component Fabrication → CNC punching, laser cutting, forming, welding, PEM installation, plating, and painting.

- Part Kitting & Staging → Parts are grouped by subassembly and job traveler for efficient workflow.

- Mechanical Assembly → Technicians use jigs, lift-assist, and fastening tools to build subassemblies and larger units.

- Electromechanical Integration → Wiring, cabling, grounding, and electronics are installed per customer drawings.

- Testing & Quality Checks → Assemblies are inspected for alignment, fastening integrity, and cosmetic finish.

- Packaging & Shipping → Custom packaging to prevent damage and simplify the next integration step.

In-House Sheet Metal Assembly Techniques

Our technicians are trained in a variety of mechanical assembly and joining techniques to ensure the strength, precision, and performance of your fabricated assemblies:

- PEM Fasteners → Self-clinching nuts, studs, and standoffs embedded into sheet metal for strong threaded connections

- Blind Rivets & Solid Rivets → Permanent fastening for joints where access to one side is limited

- Spot Welding → Resistance welding for overlapping metal surfaces in low-profile applications

- MIG & TIG Welding → For structural strength, enclosure seams, and heavier gauge materials

- Threaded Inserts → Used in softer sheet metals to create durable screw threads

- Adhesive Bonding → Structural adhesives and epoxies are applied when vibration damping or thermal isolation is required

- Tab-and-Slot & Snap Fit → For toolless interlocking of components and simplified assembly

Industries We Support

Our sheet metal assembly services are a perfect fit for OEMs building complex machinery and equipment within high-reliability industries:

- Industrial Equipment – Power units, control cabinets, motion system housings

- Medical & Laboratory – Instrument frames, shielded panels, mobile cart structures

- Semiconductor & Clean Tech – Enclosures, brackets, and subframes used in contamination-sensitive environments

- Defense & Aerospace – Ruggedized structural chassis and electronics housings

Let’s Build Together

From initial fabrication to final system integration, PEKO is your partner for precision sheet metal assembly services. Whether your build includes a few components or a few hundred, we have the in-house capabilities, dedicated teams, and engineering expertise to bring your vision to life.

Ready to get started? Contact us today to discuss your application or request a quote for your next sheet metal assembly project.