Share article:

Product Type: CNC Machine

Manufacturer: Mighty Viper

Model: Vertical Bridge Mill, #PMC-4127

Where to buy: Find a Viper Dealer

Performance Rating: 4/5

Quality Rating: 5/5

User Friendly Rating: 3/5

Price Rating: 4.5/5

Overall Rating: 4.1/5

Introduction

Mighty Viper sure has a way of living up to its name when it comes to the company’s large, over-sized mills. At PEKO, we sure have enjoyed having these large powerhouses in our facilities. Located in our corporate headquarters, along with FOUR other machines from the company’s product line, this giant is strategically placed so we can still utilize as much floor space as possible.

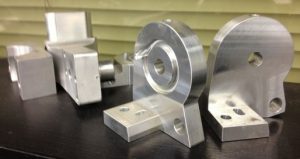

Since we are a Full-Service Contract Manufacturer of machinery and equipment, owning a large CNC machine capable of the stringent quality standards we hold ourselves accountable for became a necessity to machine the large, precision parts needed for our customers’ assemblies.

How Did PEKO Come About Using This Product?

A few years ago, we started working with a customer in the medical industry who wanted to utilize PEKO’s full-service suite to manufacture and assemble their ground-breaking, large-scale, electro-mechanical assembly. While the project has been a success overall, at the onset of our relationship with this fresh company, we were presented with two obstacles: Machining such massive parts needed for the assembly; and keeping within strict tolerances for a medical assembly which could be a life or death situation if we weren’t absolutely certain of our quality and process.

After much consideration, and plenty of intense research from our industrial engineers and upper management teams, we purchased the Mighty Viper PMC Bridge Mill. Not only do we still utilize this machine for our medical customer, we have also used this Bridge Mill to machine highly-complex precision parts for Defense customers. Like the medical industry, the Quality requirements for defense parts are extremely stringent, yet this machine has allowed us to maintain our ability in providing these complex, precision parts for our defense customers, but on a much larger scale.

What are Some Benefits We Have Seen?

- Machining Large Parts (the table size is an astonishing 157″ x 102″)

- Extremely Tight Tolerances (we have the ability to machine tolerances within 0.0005″ regularly)

- Spindle Coolant Features

- Right Angle Head

What are some Shortfalls of this equipment?

- It’s a large bulky machine–a lot of our floor space must be dedicated to the Viper’s large footprint (43’0″ x 20’0″ x 15’0″)

- Since the machine’s table is so large (which allows us to machine those large parts) the Viper can be slow moving when ripping through large chunks of raw materials

- Operators have to climb inside the machine, on their hands and knees, due to the machine’s massive table size

Price vs Value

Since we purchased this machine in an effort to actually manage the entire manufacturing and assembly of our medical customer’s large, electro-mechanical system, we needed to purchase a high value machine. This investment paid itself off in short time, and has since proven to be an irreplaceable asset for our company. Since we run this machine for both medical and defense customers, our payback has met expectations, while the parts it produces have continued to be accepted by our strict quality department.

How Well Does it Work and How is the Usability?

This bridge mill utilizes the same interface as our other Mighty Viper machines and FANUC controls, and it only took an operator two days to master this beast. Implementing this 3-axis mill into our process was a breeze and it continues to bring us a positive cash-flow into our operation.

What Were Some Alternatives we could have Pursued?

There were several alternatives we looked into as we tried to fill our need to produce high-quality, massive parts. However, since we already owned two other machines from the company, and thus had a very positive pre-existing relationship with Mighty Viper, they were able to offer us the best deal against the competition.

Conclusion

In honesty, we can’t get enough of this machine. This mill has expanded our capabilities further than what we could manufacturer prior to its purchase. The Mighty Viper Bridge Mill has also been a show stopper when we provide tours of our facilities. Sitting in the center bay in our corporate headquarters, this prize sure does grab the attention of our visitors.

Share article: