In today’s competitive machinery production landscape, OEMs and SMBs face mounting challenges. Products are increasingly sophisticated, requiring hundreds or even thousands of unique parts to come together seamlessly. For companies operating in high mix low volume (HMLV) manufacturing, the stakes are even higher: they must balance customization, complexity, and speed without sacrificing quality.

In today’s competitive machinery production landscape, OEMs and SMBs face mounting challenges. Products are increasingly sophisticated, requiring hundreds or even thousands of unique parts to come together seamlessly. For companies operating in high mix low volume (HMLV) manufacturing, the stakes are even higher: they must balance customization, complexity, and speed without sacrificing quality.

Managing complex BOMs and part flows is at the heart of this challenge. A single oversight in tracking revisions, sourcing components, or synchronizing subassemblies can result in costly delays, rework, or compliance risks. For OEMs building capital machinery or specialized equipment, success hinges on their ability to streamline these processes.

Why BOM & Part Flow Management Is Critical in Complex OEM Machinery Production

Bills of Materials (BOM) serve as the blueprint for every machinery build. In many cases, they encompass hundreds to thousands of unique part numbers, ranging from fabricated weldments to precision-machined components and purchased subsystems. The sheer volume of detail makes accuracy non‑negotiable.

Even a single mistake in revision control or part tracking can cascade into costly consequences: assemblies built to the wrong spec, shortages that halt production, or late-stage quality escapes that demand rework. These disruptions not only push delivery dates but can also erode customer confidence and increase program costs.

Well-structured BOM and part flow management provide the discipline needed to prevent these issues. By ensuring that every component is accounted for, released under the correct revision, and delivered to the right build stage, manufacturers create a stable foundation for success. This foundation becomes even more critical in environments defined by frequent design changes and shifting supply conditions—the hallmark of high mix low volume production.

Unique Challenges in High Mix Low Volume

High mix low volume environments amplify complexity. Here’s what typically drives risk and delay:

- Constantly changing designs (NPI → production ramp). Frequent ECOs, shifting form/fit/function, and evolving test requirements increase revision churn and the chance of mixed‑rev builds.

- Limited economies of scale. Small lots mean higher effective setup time per unit, tighter MOQs, and fewer price breaks—unit cost and lead time become more volatile.

- Supply chain volatility for specialty/low‑volume parts. Long‑lead motors, drives, optics, pneumatics, PLC components and certification‑bound items are prone to allocations, NCNR terms, and EOL notices.

- Mixed material model. BOMs typically blend fabricated, purchased, and consigned parts, which complicates ownership, inspection on receipt, traceability, and financial reconciliation.

- Variant proliferation. Option families and region/config builds multiply part numbers and routing paths, stressing planning and inventory accuracy.

- Complex routing and sequencing. Deep multi‑level BOMs and interdependent subassemblies make kitting and material staging fragile if not tightly coordinated.

Understanding these structural challenges sets the stage for disciplined countermeasures—BOM control, change governance, and synchronized part flow that preserve schedule, quality, and cost in HMLV machinery production.

Best Practices for Managing Complex BOMs in High Mix Low Volume Machinery Production

Digital BOM Systems & ERP Integration

Centralizing BOMs in a robust digital platform is essential for complex machinery manufacturing programs. At PEKO, we use Infor CloudSuite Industrial (CSI) to tie BOM data directly to work orders and travelers. This ensures that revision updates cascade instantly to the shop floor, preventing mixed-revision builds and improving traceability. Integration between ERP, engineering design tools, and production creates a single source of truth that eliminates manual handoffs and reduces error risk.

Early-Stage BOM Verification (NPI Support)

Before a BOM is released to production, a structured verification process helps identify risks. This includes:

Before a BOM is released to production, a structured verification process helps identify risks. This includes:

- BOM audits to confirm accuracy of part numbers, quantities, and revisions.

- Critical parameter worksheets and Failure Mode and Effects Analysis (FMEA) to validate that functional requirements are met.

This upfront diligence prevents late-stage surprises and sets a stable foundation for the transition from NPI into scaled builds.

Supply Chain Synchronization

In high mix low volume environments, long-lead and specialty items can derail schedules if not addressed early. Best practices include:

- Aligning forecasts and demand signals with suppliers as soon as BOMs stabilize.

- Using hybrid procurement plus consignment strategies, where a contract manufacturer can manage a portion of the supply chain while OEMs consign critical components.

This approach balances risk, reduces cash tied up in inventory, and ensures material readiness at the right time.

Part Kitting & Subassembly Strategies

Managing thousands of parts at final assembly in machinery production is inherently risky. Pre-staging and kitting strategies reduce complexity and improve build velocity. Tactics include:

- Pre-staging subassemblies so technicians focus on higher-value integration instead of chasing individual components.

- Implementing disciplined kitting processes where each kit is sealed, revision controlled, and delivered with everything required for a specific traveler.

By shifting complexity upstream into controlled kitting and subassembly workflows, OEMs gain efficiency, accuracy, and smoother final assembly execution.

These best practices form the backbone of disciplined BOM management in HMLV machinery production, turning engineering intent into repeatable execution. The next step is to consider how to optimize part flows—from receiving dock to final integration—to ensure that materials not only exist in the system but also move through it seamlessly.

How to Optimize Part Flows in HMLV Machinery Production

Custom Assembly Cells for Flow Efficiency

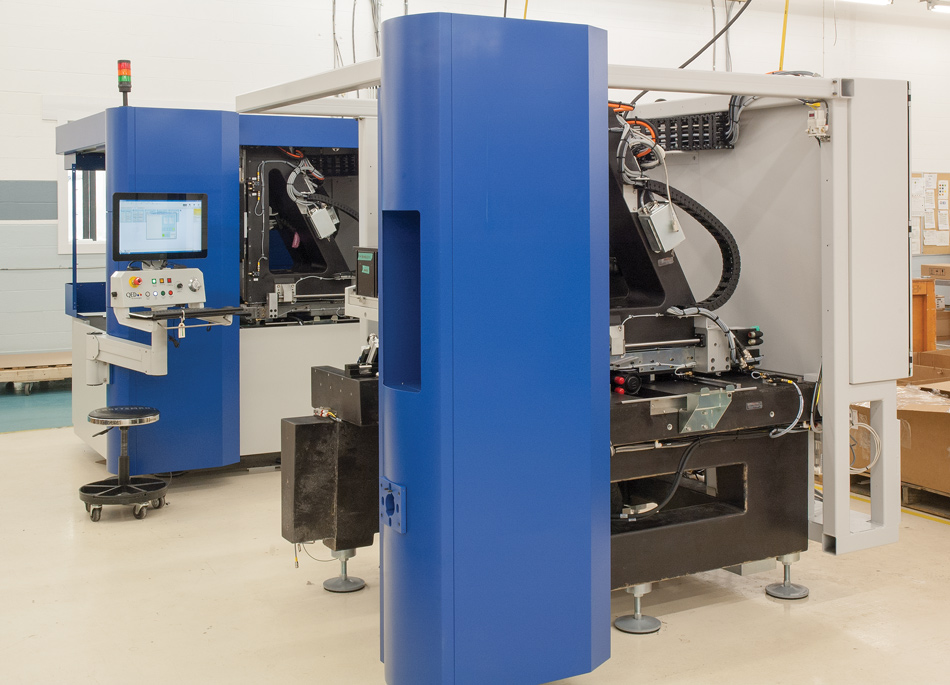

Optimizing part flows in machinery production often begins with the physical layout of the build environment. At PEKO, we configure dedicated assembly cells for each program. These cells are designed to support both prototype and production phases, allowing teams to transition seamlessly as volumes increase.

Optimizing part flows in machinery production often begins with the physical layout of the build environment. At PEKO, we configure dedicated assembly cells for each program. These cells are designed to support both prototype and production phases, allowing teams to transition seamlessly as volumes increase.

By aligning tooling, fixtures, and resources within a program-specific space, OEMs reduce material movement, eliminate bottlenecks, and create a repeatable flow for complex assemblies in high mix low volume production.

Clear-to-Build & Traceability Systems

Ensuring readiness before assembly is critical in HMLV manufacturing. “Clear-to-Build” checks confirm that no work order is released until all required components are on hand. This prevents idle technicians, mid-build shortages, and costly rework.

To maintain control as parts move through the system, PEKO integrates barcode-driven part tracking tied to ERP travelers. Every component is scanned at each stage, providing real-time visibility into part location, revision status, and quality checkpoints. This traceability ensures compliance for regulated industries and instills confidence in OEM partners that assemblies are built to the correct spec every time.

Risk Mitigation in HMLV Production Part Flows

High mix low volume machinery builds are especially vulnerable to part risks such as End-of-Life (EOL) components or supplier disruptions. PEKO mitigates these risks by:

- Actively monitoring for EOL notifications through supplier alerts and internal MRP flags.

- Establishing alternate sourcing pathways and qualification processes so production isn’t jeopardized by single-source dependencies.

- Aligning with OEMs early to determine redesign or long-term buy strategies for critical parts.

This proactive stance allows programs to maintain momentum even when market conditions shift, ensuring continuity in both prototype and production environments.

Together, these strategies create a tightly controlled material flow that complements disciplined BOM management. By combining program-specific assembly cells, readiness checks, and proactive risk management, OEMs in HMLV manufacturing environments can ensure their part flows remain efficient, traceable, and resilient—setting the stage for higher reliability and faster time-to-market.

The PEKO Approach to Complex BOMs & High Mix Low Volume Machinery Production

PEKO brings more than 55 years of experience in machinery and equipment production, making us a trusted partner for OEMs tackling complex BOMs and high mix low volume programs. Our approach is built on:

- Vertical integration. With in-house machining, sheet metal fabrication, welding, and assembly capabilities, PEKO controls every step of the build. This reduces reliance on external suppliers, shortens lead times, and ensures quality.

- ERP + QMS integration. Our systems combine enterprise resource planning with a robust quality management system to provide full revision control, part traceability, and compliance across regulated industries.

- Proven success at scale. From MRI systems and optical polishing machines to large print systems, PEKO has demonstrated the ability to deliver highly complex machinery builds at production scale.

Our integrated approach positions OEMs for success in high mix low volume manufacturing by combining decades of expertise with modern systems and scalable processes.

Key Takeaways for Machinery Manufacturers

- Precision BOM management and controlled part flows are non‑negotiable. In high mix low volume manufacturing, even small errors can lead to major delays, cost overruns, or compliance risks.

- The right manufacturing partner matters. Successful OEMs align with contract manufacturers that bring ERP rigor, resilient supply chains, and deep assembly experience to every build.

- Engage early to avoid disruption. By partnering with a capable contract manufacturer at the outset, OEMs can sidestep shortages, manage revisions effectively, and maintain predictable schedules.

These takeaways highlight why disciplined processes and trusted partnerships are essential for thriving in modern machinery production environments.

Ready to Streamline Machinery Production?

PEKO helps OEMs manage complex BOMs and part flows to ensure on-time, compliant machinery production. Whether you’re scaling a new platform or outsourcing a mature build, our team brings structure to high-mix, low-volume manufacturing. → Talk to Our Team About Your Next Machinery Build