When it comes to outsourcing manufacturing, you’ll want to choose a company that can help you each and every step of the way. Whether it’s design engineering that still needs fine-tuning or making sure that your design can be manufactured–and repeated–make sure you find a full-service contract manufacturing company with wide-ranging in-house capabilities.

At PEKO, we are proud to offer our clients with an extensive list of in-house capabilities. Not only does this set us apart from other contract manufacturers, but it also allows us to provide our customer base with a turnkey manufacturing solution for all their manufacturing needs from start to finish.

What is Full-Service Contract Manufacturing?

From Engineering to Prototyping to Production

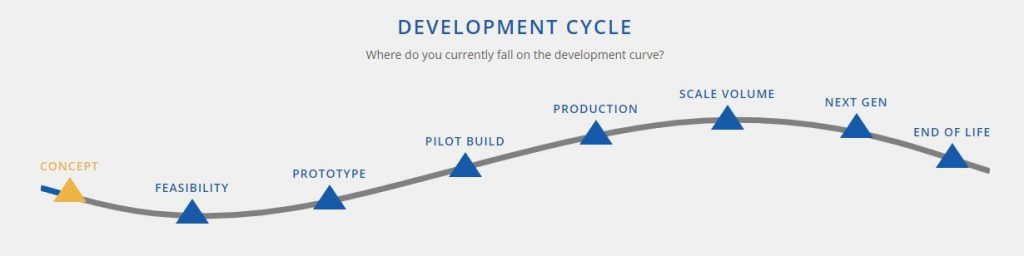

A true full-service contract manufacturing company will help their OEM customers through every step of the product development cycle, all the way into the manufacturing and production curve. They will have an experienced engineering department that is staffed with eager professionals who are fully prepared to assess your prints and BOMs and confirm that everything in your design can be manufactured, easily.

A full-service contract manufacturing partner will understand the importance of:

- vetting your technology before it hits the market,

- confirming all print packages are ready for production, and

- ensuring the proper action plans are in place once you’re ready to “scale-up” production.

If you’re looking to outsource the assembly and manufacturing of your machinery, you’ll want to look for a company that will take you through their development cycle–even if you’ve already built a prototype that works. When new customers engage with PEKO, we typically walk them through the beginning stages of the development cycle, even if they have already built a prototype

With this integrated approach, the engineering and manufacturing teams work closely together until both teams are certain that your major mechanical assembly can be reproduced perfectly each and every time.

They’re Invested in Your Success

Sometimes sub-assembly quantities may need to be “ramped-up,” in a moment’s notice. A full-service contract manufacturer will be sure to have the proper plans in place to allocate resources once a sudden increase in demand takes place. Apart from just your own equipment that is manufactured by the CM, you should be confident that your partner is reinvesting in:

- themselves

- their own equipment, and

- their employees.

A CM that adapts to the constant changes within the industry should give OEMs the peace of mind knowing that their product will continue to be produced as efficiently as possible with up-to-date equipment. Company-wide efforts should be made to execute continuous improvements which will ultimately increase both profitability and marketability for their customers. If you’re looking to outsource to a contract manufacturer, check to make sure the company is incorporating lean practices, six sigma, TOC and other methods to maintain your sustained value.

Vertically Integrated Capabilities

A true full-service contract manufacturing organization will have a vertically integrated business model, which sets the organization apart from lower-end contract assemblers. If you’re looking to outsource, be sure to pick a company that has the capability to manufacture at least 50% of your major mechanical assembly, in-house. As an OEM, don’t let a CM that relies on heavily on outside vendors impact your strict deadlines. The more a CM can do under their own roof, the more control they have on meeting the deadlines you both agreed upon.

For example: At PEKO, we stand by our abilities to do the following in-house:

- Precision CNC Machining

- Milling & Turning

- Reverse Engineering

- Design for Manufacturing

- Sheet Metal Fabrication

- Welded Frames

- Powder Coating

- Electrical Wiring

- Assembly & Testing

- Clean Room Assembly

- Inspection & Quality Control

- Procurement

Apart from executing strict deadlines, the more a CM can do in-house, the more confidence you can have in your data protection. If you have “break-through” technology, then you’ll need the reassurance of IP protections. The fewer outside vendors a CM works with means that there are far less companies viewing sensitive information that is vital to an OEM’s core business. If you’re lucky enough to come across a company that works in the defense or other highly regulated industries, like PEKO, then you can rest assured that the company already has strict guidelines in place to ensure data protection for its defense customers.

Choose Full-Service Contract Manufacturing

Not all companies use the title “contract manufacturer” in the same way. If you’re looking for a true vertically integrated company, that provides full full-service contract manufacturing solutions, make sure you properly vet out your selection. Once you’ve narrowed down your selection, we recommend you take a tour of each company’s facilities to figure out which company will be the best fit for your needs. While there may be plenty of disadvantages with offshoring, manufacturing is currently booming in the USA for companies looking to outsource.

Before touring the selected facilities, be sure to download our Free Contract Manufacturing Checklist for all the essential necessities you’ll want to look out for. If you’re interested in utilizing all of the fantastic capabilities PEKO has to offer, request a quote to speak with one of our engineers, today!