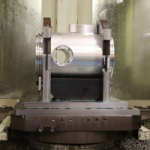

Custom CNC Fixture Design

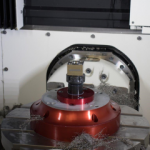

PEKO’s CNC machining division employs dedicated tooling engineers for its machining fixture design. To fully utilize our precision parts and assemblies business, PEKO must produce hundreds of custom designed machining fixtures every year. A well designed workholding fixture is part of a successful precision parts manufacturing business line. If you are contacting PEKO for precision parts and assemblies, your job will almost certainly be reviewed by a machining fixture design engineer. We create CAD designs and perform simulations based on the expected behavior of the machine and material. These CAD models are then replicated in their real form and used to produce parts on our CNC machines.

Types of Machining Fixture Design

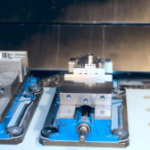

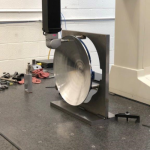

Our engineering team can design milling and turning fixtures of most types. The major factors to determine the tooling are part size, material, machine size, configuration, quantity and operation. Our engineering team takes all of these into account when CNC fixture design is required for very complicated parts. Some common workholding fixtures we design are:

- Custom vice jaws

- Custom tombstone fixtures

- Stand-alone fixtures

- Jigs

- Pneumatic clamping

- Robotic fixtures

- Vacuum chucks

- Indexing or trunnion tooling

- Lathe/Turning fixtures

- Modular Fixtures

- Pallet Changer workholding

- Inspection tooling

Advantages of In-House Milling and Turning Tooling Design

Keeping tooling design in-house is an enormous benefit to our precision parts and assemblies customers. Being vertically integrated means having an internal supply chain of metal components to feed our contract manufacturing customers. From CNC fixture design to vacuum chucks to modular fixtures, PEKO’s team is ready. We’ll deploy our engineering team to your difficult fixtures and tools today.

PEKO is constantly improving our machining department as we continue to expand and reinvest into our organization. For the most up to date information on our machine shop capabilities, please visit our Facilities Page.