Share article:

Don’t Fall into a Precision Machining Trap:

If you’re anything like the OEMs I’ve talked to, you have a horror story about a shop that has let you down in ways you never even thought of. From going out of business with customer WIP to forgetting to run parts to not even using the right material, anything can and has happened. Precision CNC Machining isn’t easy and a low barrier of entry can let anyone into the business. There are a lot of misconceptions in manufacturing and your average precision machine shop is no exception to the rule. This post is a good starting point that will clear the air about precision machine shops and should help you choose the right one for you.

1. Myth #1: All precision machine shops are created equal

As I’ve mentioned in another post, there’s a lot that make a great precision machining house. Many people buy into a belief that one machine shop is just like the next. This couldn’t be farther from the truth. Precision Machining is a complex business and each shop can best serve different customers. Factors like financial stability, quality system, machine size, and manufacturing processes can create a huge difference from shop to shop. It’s easy to write them all off as the same but the truth is a lot of investigation should go into finding the right shop for anyone who has a precision cnc machining initiative to satisfy.

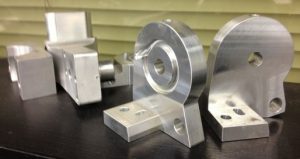

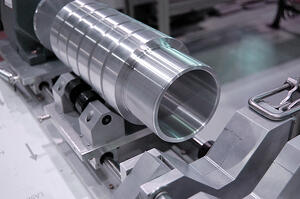

2. Myth #2: Precision machining is all about the equipment

For those of us in the industry, we love to look at different companies’ facilities lists. A facilities list shows all the equipment that a company has on the shop floor. These lists can be very impressive and often times are meant to be. Companies boast the biggest and newest machinery. While that is an important part of the puzzle, that is not the entire picture. Just as a race car needs the appropriate driver and pit crew to be a winner, precision machinery and equipment needs the right operators and manufacturing expertise to create parts fit for a customer. Don’t always assume the best machinery means the best shop. Look at the people and the processes that make up the shop to ensure you’re working with the right company.

3. Myth #3 Lowest price is a good indicator for precision cnc machining success

CONCLUSION:

At the end of the day, we all want precision cnc machining services fast and cheap. It is important to remember the myths above. These can serve as a guide when choosing the right supplier for the right type of parts. Precision machine shops are still bountiful across the country but they are certainly not created equal. Choose the shop with the right team and processes and your parts buying experience will be a success. For more information on how the PEKO team can assist you in Precision CNC Machining, contact me direct or click below.

Share article: