Automated Storage and Retrieval System (ASRS)

Challenge

A worldwide leader in industrial warehousing automation solutions faced challenges with their supply chain for their automated storage and retrieval system (AS/RS or ASRS). Their current contract manufacturer was unable to meet increasing demand for the product, leading them to seek alternative solutions. However, they soon discovered that they did not have the rights to the technical information that belonged to their former supplier. These documents were critical to accurately reproduce the automated storage and retrieval system, which consisted of hundreds of custom and off-the-shelf components. To resolve the issue, the company urgently sought a new contract manufacturing partner who could reverse engineer the entire system and develop the necessary technical documentation for its continued production.

Solution

The customer made the decision to partner with PEKO after evaluating their options. PEKO’s reverse engineering expertise, prototype manufacturing capability, and IP protections aligned well with the customer’s needs. They also recognized that the partnership could open the doors to utilizing our comprehensive contract manufacturing capabilities in the future, if necessary.

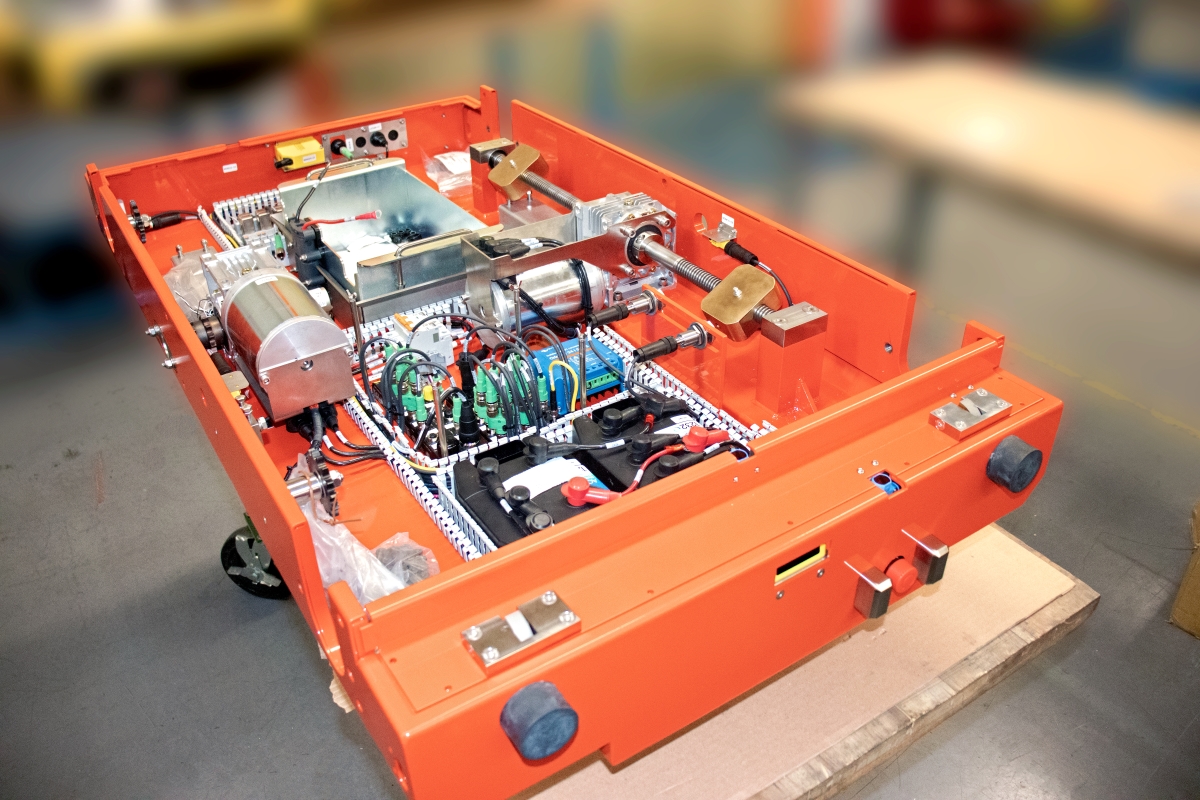

PEKO’s first step was to disassemble a complete automated storage and retrieval system provided by the customer to understand its inner workings. They assembled a multi-functional team of engineers, technicians, and inspectors to handle this process and meticulously document every component. They then identified alternatives for obsolete or unidentifiable components and created accurate 3D models of custom components found within the unit. A detailed review was conducted on each part for functionality, manufacturability, and cost. The system was then optimized for design for manufacturability (DFM) by implementing changes such as slot-and-tab construction without compromising functionality or the project schedule.

A complete mechanical and electrical documentation package was prepared, including CAD models, prints, and wiring schematics, to ensure accurate replication of the ASRS system. A comprehensive bill of materials (BOM) was also generated. PEKO further validated their work by manufacturing a small batch of functional prototypes using their vast internal capabilities, including machining, welding, sheet metal, mechanical assembly, electrical/controls integration, and procurement, to ensure that the documentation developed by PEKO could perfectly replicate the sample automated storage and retrieval system provided by the customer.

SUccess

PEKO’s expertise proved to be a game-changer for the customer, enabling them to take control of their own destiny for any future production of their automated storage and retrieval system for the first time in over 10 years. Through meticulous planning and documentation, PEKO developed a complete and accurate technical documentation package, including CAD models, 2D prints, electrical schematics, and a bill of materials. This was provided to the customer as their sole property, along with a significant list of DFM and cost-down opportunities.

PEKO also provided the customer with multiple prototype units accurate enough to be put in service alongside existing systems in the field. This level of attention to detail and commitment to quality is what sets PEKO apart as a trusted partner in delivering comprehensive engineering and contract manufacturing solutions. The customer now owns the complete design and intellectual property of their automated storage and retrieval system, granting them manufacturing flexibility that was previously beyond their reach.

Get in touch with us today to see how PEKO Precision can meet the needs of your project.