When builds are complex and the stakes are high, the choice of assembly company isn’t about piece price—it’s about total risk, speed, and compliance. Offshore suppliers can look attractive on paper, but tariffs, delays, and compliance friction erode the math. Here’s why a U.S.-based partner changes the equation.

1) U.S. Jurisdiction & Enforceable IP Protection

When your program lives inside the United States, your IP is governed by U.S. law—period. That means clearer contracts, stronger trade-secret remedies, and practical enforcement through U.S. courts. For high-consequence builds (novel mechanisms, firmware, controls), a domestic partner reduces exposure from cross-border transfers, foreign discovery, and multi-jurisdiction disputes.

When your program lives inside the United States, your IP is governed by U.S. law—period. That means clearer contracts, stronger trade-secret remedies, and practical enforcement through U.S. courts. For high-consequence builds (novel mechanisms, firmware, controls), a domestic partner reduces exposure from cross-border transfers, foreign discovery, and multi-jurisdiction disputes.

Why it’s unique to the US: Jurisdiction and enforcement mechanisms are inherently nation-specific; you only get U.S. legal recourse with a U.S. manufacturing base.

2) Export-Control Simplicity for Controlled Tech (ITAR/EAR)

Defense, aerospace, and certain dual-use technologies trigger U.S. export rules. Keeping design data, prototypes, and production entirely within the United States minimizes licensing events, visitor restrictions, and foreign-national access reviews. A U.S. assembly company can maintain controlled technical data on U.S. soil and align workflows to ITAR/EAR without overseas handoffs.

Defense, aerospace, and certain dual-use technologies trigger U.S. export rules. Keeping design data, prototypes, and production entirely within the United States minimizes licensing events, visitor restrictions, and foreign-national access reviews. A U.S. assembly company can maintain controlled technical data on U.S. soil and align workflows to ITAR/EAR without overseas handoffs.

Why it’s unique to the US: No export = no export filing. You can’t recreate “domestic-only” simplicity with an out-of-country supplier.

3) Eligibility for U.S. Domestic-Preference & Content Rules

Many U.S. public-sector and prime-contractor procurements require domestic manufacturing or content thresholds (e.g., Buy American/Buy America frameworks, Berry Amendment in defense, TAA/DFARS flow-downs). A U.S. plant gives you the manufacturing location and documentation needed to qualify for these frameworks and to receive domestic-preference scoring.

Why it’s unique to the US: These are U.S. statutes and contract clauses tied to where production occurs—non-U.S. builds typically don’t qualify.

4) Tariff, Duty & Trade-Action Avoidance for U.S. Deliveries

Manufacturing in the United States avoids import tariffs, anti-dumping/countervailing duties, and ocean-freight surcharges on finished goods entering the United States. This stabilizes your landed-cost model and reduces volatility in pricing to U.S. customers over multiyear agreements.

Why it’s unique to the US: Tariffs and AD/CVD apply to imported goods; U.S. production for U.S. sale removes that exposure on finished assemblies.

5) “Made in USA” Claims & Market Access

Certain U.S. buyers—government, utilities, health systems—value or require American origin. When your BOM and processes meet thresholds, a U.S. assembly company enables origin claims aligned with FTC guidance and downstream channel requirements.

Why it’s unique to the US: Origin claims are jurisdictional; only U.S. manufacturing can support genuine “Made in USA” positioning.

6) Easier U.S. Agency, Prime-Contractor & Regulated-Market Audits

FDA, DoD/DOE primes, utilities, and other U.S. audit-heavy customers often require on-site audits, witness testing, or document reviews under U.S. rules. Conducting these activities domestically simplifies site access, background checks, chain-of-custody for samples, and retention requirements—without visas, export licenses, or international travel.

FDA, DoD/DOE primes, utilities, and other U.S. audit-heavy customers often require on-site audits, witness testing, or document reviews under U.S. rules. Conducting these activities domestically simplifies site access, background checks, chain-of-custody for samples, and retention requirements—without visas, export licenses, or international travel.

Why it’s unique to the US: Audit frameworks and physical oversight by U.S. entities are streamlined when the plant and records are in the United States.

7) U.S. Data Residency & Secure Handling of Controlled Information

Housing technical data (CAD, firmware, test results) on U.S. servers and restricting access to U.S. persons can be essential for controlled programs. A domestic assembly company can implement U.S.-hosted PLM/ERP instances, vetted subcontractors, and onshore labs to keep digital and physical artifacts inside U.S. boundaries.

Why it’s unique to the US: Data residency and “U.S. persons only” controls rely on geography and citizenship; you can’t mirror that with non-U.S. production.

Why Choose PEKO as Your U.S. Assembly Company

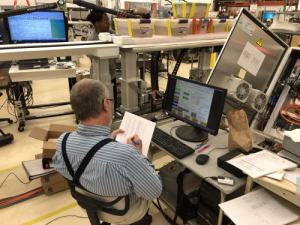

PEKO is a vertically integrated, U.S.-based assembly company purpose-built for complex equipment and regulated industries.

At-a-glance credibility:

- Integrated build: CNC machining, sheet metal, welding/finishing, wiring/panels, electromechanical integration, and functional test—managed under one program.

- Program discipline: DFM/DFA, pilot → qualification → ramp, documented QMS, and transparent metrics.

- Compliance alignment: ITAR‑friendly workflows, ISO 9001:2015 / AS9100D / ISO 13485:2016 support, and customer/third‑party audit readiness.

- Domestic-content support: Entirely U.S.-based manufacturing footprint to help satisfy domestic-preference and origin requirements.

- Secure handling: On-shore data practices and controlled access for sensitive projects.

US-Based Assembly Company FAQs

- What does an assembly company do? An assembly company integrates components—machined parts, sheet metal, wiring, electronics—into finished products or sub-assemblies with documented processes and testing.

- Which advantages are truly unique to a U.S.-based partner? Seven advantages unique to a U.S.-based assembly company: U.S. jurisdiction and IP enforcement; ITAR/EAR simplicity (no export events); domestic-preference eligibility (Buy American/DFARS); tariff/duty insulation on U.S.-bound finished goods; authentic “Made in USA” claims; easier U.S. agency/prime audits; and U.S. data residency limited to U.S. persons.

- How does U.S. location actually shorten lead time? No customs or cross-border export reviews, same-time-zone decisions, day-trip audits/witness builds, and continental trucking/air. Those U.S.-only factors compress ECO cycles and reduce buffers—turning changes same day instead of “next week.”

- How does domestic assembly lower total landed cost (beyond piece price)? Eliminated duties/AD-CVD on finished goods, shorter pipelines (less WIP and buffer inventory), fewer expedites and supplier-management trips, and reduced pricing volatility from trade actions—together driving a structurally lower TLC over multiyear agreements.

- Can a U.S. assembly company help us qualify for domestic-preference or “Made in USA” claims? Yes—when your BOM/processes meet the applicable thresholds. A U.S. partner provides location, content documentation, supplier declarations, and origin/traceability records required for Buy American/Buy America and supports FTC-aligned “Made in USA” claims where eligible.

- How does keeping work U.S.-only affect export-control workload (ITAR/EAR)? It removes most licensing triggers: no exports of technical data, fewer foreign-national access reviews, and simpler supplier vetting. If you later ship internationally, you start from a controlled, documented baseline rather than reverse-engineering compliance.

- How does U.S. data residency protect sensitive designs? CAD/firmware/test data stays on U.S. infrastructure with U.S.-persons access. That reduces cross-border exposure, helps satisfy controlled-data requirements, and speeds secure collaboration—especially when fixture, test, or firmware changes occur.

Bottom Line: Why a U.S. Assembly Company Wins

Choosing a U.S.-based assembly company unlocks advantages you can’t reproduce offshore—U.S. jurisdiction and IP enforcement, ITAR/EAR simplicity, domestic-preference eligibility, tariff/duty avoidance, streamlined U.S. audits, and U.S. data residency. In practice, those levers yield shorter lead times, real-time collaboration, materials agility, customer-facing proximity, and a lower total landed cost for U.S.-bound programs.

Ready to start your next assembly program with a U.S. partner?

Submit your project to PEKO using the form below.