COTS items, also known as commercial off-the-shelf items, often make up almost half of the value of a machine. Something that’s pretty cool from the standpoint of an industrial machinery manufacturing company is the number of different COTS items we get to play with.

Since we don’t always get to spec out the COTS items used in the equipment we build, our engineers and machine building teams get exposed to dozens of categories, hundreds of brands, and thousands of COTS items each year. This hands-on knowledge is invaluable to running such a successful company.

Today let’s look at some categories and brands that are popular in the machines we’ve built over the years.

1. Programmable Logic Controllers (PLC)

One COTS item we frequently use in machinery builds is PLCs. PLCs, also known as programmable logic controllers, are rugged computers used for industrial automation applications. Electrical and controls engineers program and integrate PLCs as the brains of a machine.

PLCs have inputs and outputs and are connected to other devices within the system. Industrial manufacturing companies spec out PLCs to run their machines and use ladder logic based on the inputs to drive the outputs for devices and components in the machine.

PLCs have inputs and outputs and are connected to other devices within the system. Industrial manufacturing companies spec out PLCs to run their machines and use ladder logic based on the inputs to drive the outputs for devices and components in the machine.

Oftentimes, we see prototypes or early-stage machinery that are driven by Windows-based systems, but the commercialization process requires conversion to more industrial-hardened equipment like PLCs. Without PLCs, there could be no industrialized machinery. PLCs come in different configurations for different applications. For industrial machinery, the most common physical configuration will be rail mounted.

Open the back panel of any machine and you’ll see at least one PLC running the show amongst other electrical counterparts. Some popular brands for PLCs are:

2. Industrial Power Supplies

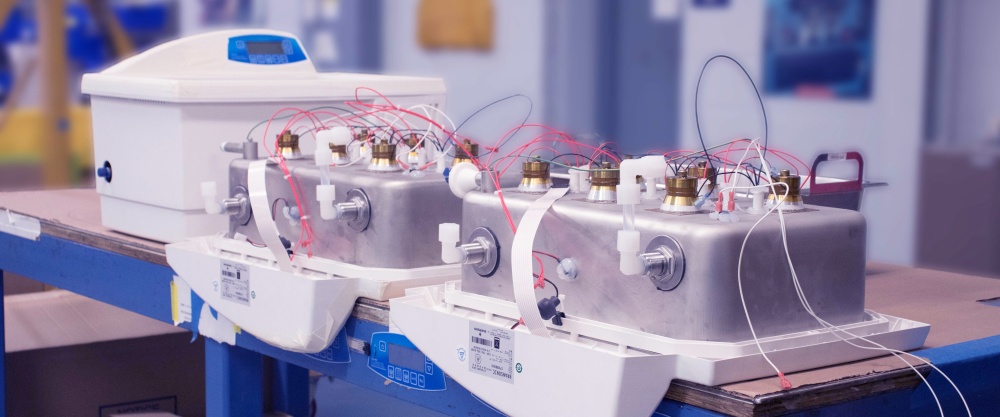

Our next most popular COTS item for machinery is industrial power supplies. In simple terms, industrial power supplies are used to turn the AC voltage of your plant into the DC voltage required by the components in your machinery. The three most common types of power supplies are linearly regulated power suppliers, unregulated power supplies, and switching power supplies.

Typically, an electrical engineer will choose the correct power supply for the design in early phases of the equipment lifecycle. This choice is made based on various usage factors like load, voltage ranges, end product, regulations (custom medical equipment comes to mind), installation type and a host of others.

A great way to spec your industrial power supply is to work directly with the power supply manufacturer or distributor to ensure the power supply you choose is properly suited for the application you are configuring.

Look inside the back panel of any machinery and you’ll notice that there will be various power supplies integrated, maybe handling the same time of job, maybe handling different jobs within the machine. Here are some of the most common industrial power supply brands that we’ve seen integrated into machinery systems:

3. Sensors

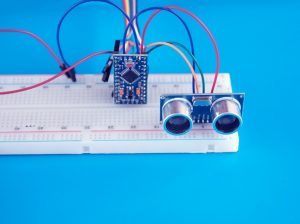

Another popular type of COTS item we see is sensors. Much like your hands can feel and your tongue can taste, sensors deliver information to a processing unit like a PLC. They use various methods like pressure, resistance, heat, and electromagnets to function.

Industrial machinery manufacturing companies lean on dozens of types of sensors to give the machine input capabilities. Some of the most common sensors we have found in machinery or equipment are proximity, capacitive, load cell, RTD, and reflective sensors. Each has not only unique sensing types but also many models for specific applications.

4. Human Machine Interfaces (HMI)

The final type of COTS that we most typically see at HMIs. HMIs, also called Human Machine Interfaces, are devices that an operator uses to control machines and equipment, often with visual displays (screen) and physical input hardware (keypads/keyboards/touch screens).

The final type of COTS that we most typically see at HMIs. HMIs, also called Human Machine Interfaces, are devices that an operator uses to control machines and equipment, often with visual displays (screen) and physical input hardware (keypads/keyboards/touch screens).

HMIs typically comprise some combination of hardware and software to ensure the inputs and outputs of the machine can be properly communicated back and forth from operator to machinery. These HMIs are used by industrial machinery manufacturing companies to provide custom solutions for their machines.

Usually, you would see these machines directly attached to a machine, but more recently we are seeing them used remotely. Custom machinery that is built by PEKO and off-the-shelf machinery, like CNC machines, all have an HMI for operator use. When integrating HMIs, there is usually some level of software debug, and the hardware needs to be integrated into the back panel with the PLCs and industrial power supplies.

Commercial off-the-shelf items (COTS items) are common to any piece of equipment produced by industrial machinery manufacturing companies. COTS items often make up about 50% of the value of the machine, so proper selection is key.

Today we’ve touched on a handful of categories and gave you some helpful resources to find and choose the COTS items for your industrial machinery. The next step is to contact a local distributor or rep to help you make your selection.

If you’ve got some new machinery you need to be built with some of these products or similar, use our Guide to Choosing a Machinery and Equipment Contract Manufacturer to help you decide on the best pick for your business.