Why Custom Fabrication Matters

Custom fabrication is not simply “making parts” — it’s about engineering solutions that mass production cannot achieve. When tolerances are tight, geometries complex, or materials demanding, custom fabrication provides the precision and process flexibility required.

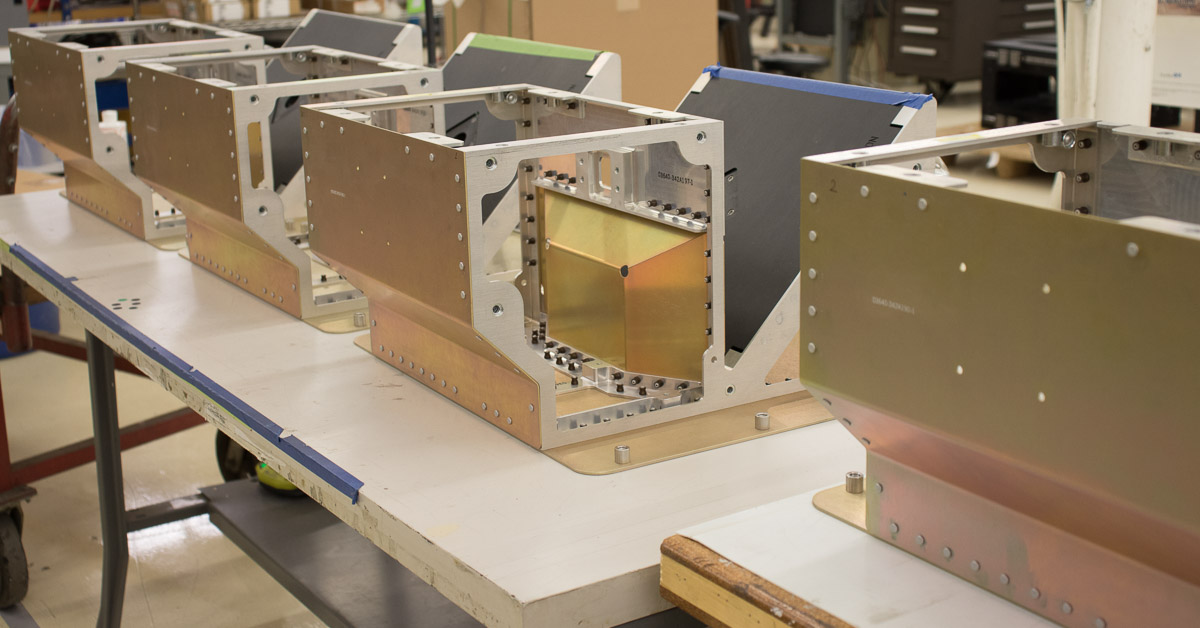

Take aerospace, for example: a sheet metal bracket formed from 7075 aluminum must hold a bend radius tolerance of ±0.010″. Off-the-shelf hardware cannot meet these requirements.

Or consider medical devices: stainless sheet housings demand laser cutting, CNC forming, and TIG welding, all while meeting FDA standards for corrosion resistance and electropolished finishes.

These cases highlight why industries like aerospace, medical, and automotive rely on custom sheet metal fabrication—it ensures that components integrate flawlessly into assemblies, comply with regulatory standards, and perform under demanding conditions.

Defining Your Custom Fabrication Needs

Successful outsourcing begins with clear communication of scope and specifications. For sheet metal parts, this includes:

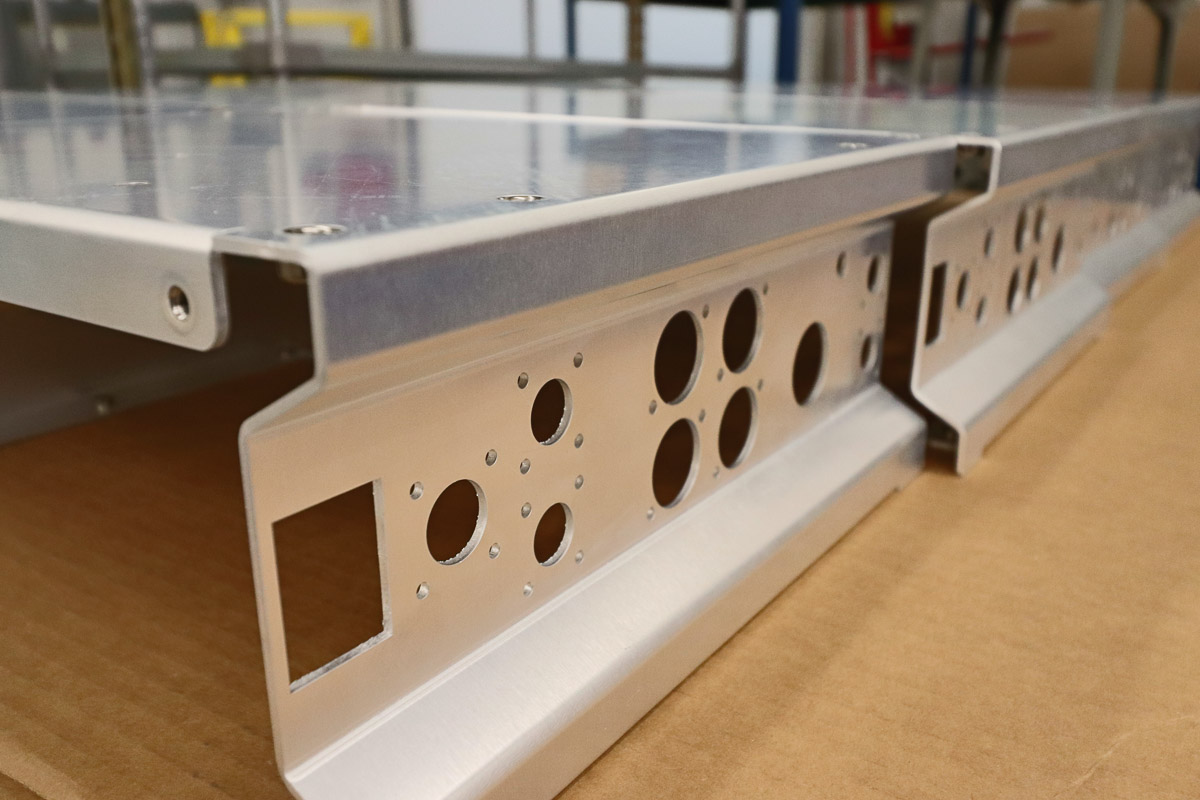

- Dimensions and tolerances: e.g., ±0.005″ flatness on a laser-cut panel.

- Material selection: aluminum for lightweight aerospace parts, stainless for corrosion resistance in medical devices, or cold-rolled steel for automotive housings.

- Operating environment: Will the part face vibration, sterilization, or exposure to heat?

CAD models with GD&T annotations provide the precision blueprint your custom fabrication partner needs. For example, a medical device sheet housing might specify 16-gauge stainless, formed with tight bend radii, and finished with passivation. Getting this detail right up front prevents costly rework later.

Selecting the Right Custom Fabrication Partner

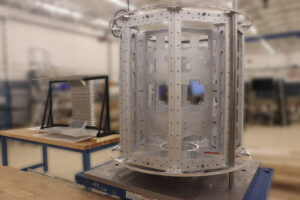

The right partner for custom fabrication outsourcing is more than just a job shop—they’re an extension of your engineering team.

Look for:

- Process capabilities: CNC machining, turret punching, laser cutting, press brake forming, MIG/TIG welding, and powder coating.

- Material expertise: from titanium sheet to specialized alloys like Inconel.

- Quality systems: ISO 9001, AS9100, or medical-grade certifications.

- Inspection resources: CMMs, surface finish measurement, and weld qualification.

For instance, an automotive enclosure requiring sheet metal laser cutting + robotic press brake forming demands a shop with both the equipment and expertise to ensure repeatability at scale.

Balancing Cost, Lead Time, and Quality

The “iron triangle” of custom fabrication—cost, lead time, and quality—requires deliberate trade-offs.

- Cost: A vendor using older plasma cutting equipment may offer lower prices, but fiber laser cutting delivers faster cycle times and cleaner kerfs that save money downstream in finishing.

- Lead time: Automated sheet handling can cut days out of production schedules for high-volume jobs.

- Quality: Precision bending of sheet metal parts requires well-maintained press brakes and skilled operators who understand springback and bend allowances.

Real-world example: a large-volume run of sheet metal chassis. Choosing a shop with automated forming reduces unit cost long-term, even if initial tooling is more expensive.

Managing Custom Fabrication Projects

Managing outsourced custom fabrication projects isn’t “place and pray”—it’s structured, proactive, and collaborative.

- Clear acceptance criteria: Specify flatness, hole alignment, weld strength, and finish requirements.

- Regular progress updates: Weekly production check-ins reduce surprises.

- Flexibility: Sheet metal prototypes often need small design tweaks before production; your partner should be capable of agile iteration.

Example: an aerospace heat shield project required progressive die stamping for thin-gauge stainless, with multiple prototypes adjusted for springback before final approval. A vendor with in-house engineering support accelerated this transition.

Intellectual Property and Risk Management

Your CAD files, flat patterns, and process details are valuable assets. Protect them with:

- NDAs and contracts defining ownership of designs and tooling.

- Secure file transfer protocols and vendor cybersecurity compliance.

- Clauses preventing replication or disclosure of proprietary sheet metal designs.

This ensures you benefit from outsourcing custom fabrication without compromising innovation.

Building Long-Term Relationships with Your Custom Fabrication Supplier

The best results come from partnerships, not transactions. Vendors who consistently deliver high-quality custom fabrication services should be treated as long-term collaborators:

- Pay on time and recognize their performance.

- Engage them in early design discussions—often they can suggest alternative bends, welds, or finishes that cut cost.

- Foster collaboration to unlock design-for-manufacturing improvements.

Example: a long-term medical OEM partner re-engineered a laser-cut sheet metal frame to reduce the number of welded seams, improving both structural integrity and cost efficiency.

Final Thoughts

Final Thoughts

Outsourcing custom fabrication isn’t just about finding a vendor—it’s about choosing a partner who can bring your designs to life with precision, efficiency, and quality.

By clearly defining your requirements, selecting the right partner, and fostering long-term collaboration, you’ll set your projects up for success while reducing risk and cost.

If you’re ready to explore how outsourcing can streamline your custom fabrication needs, connect with PEKO today.

Our team specializes in complex, regulated industries—from aerospace to medical devices—and we’ll help you turn your design challenges into production-ready solutions.

Our team specializes in complex, regulated industries—from aerospace to medical devices—and we’ll help you turn your design challenges into production-ready solutions.

Free Resource:

Want a deeper checklist for supplier vetting? Download PEKO’s guide to selecting a sheet metal fabrication supplier by filling out the form below.