What Are Wire EDM Services?

PEKO’s wire EDM services are just another strong part of our manufacturing portfolio. Our wire EDM machining services bring a tight tolerance capability that can be used on tooling, hard metals, and unique geometries.

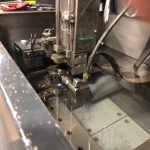

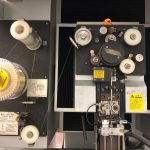

To achieve this, we have a half dozen wire EDM machining centers and highly skilled operators. Our programmers and operators work from prints and models to generate the parts necessary in the wire EDM machining process.

What Is Wire EDM Machining?

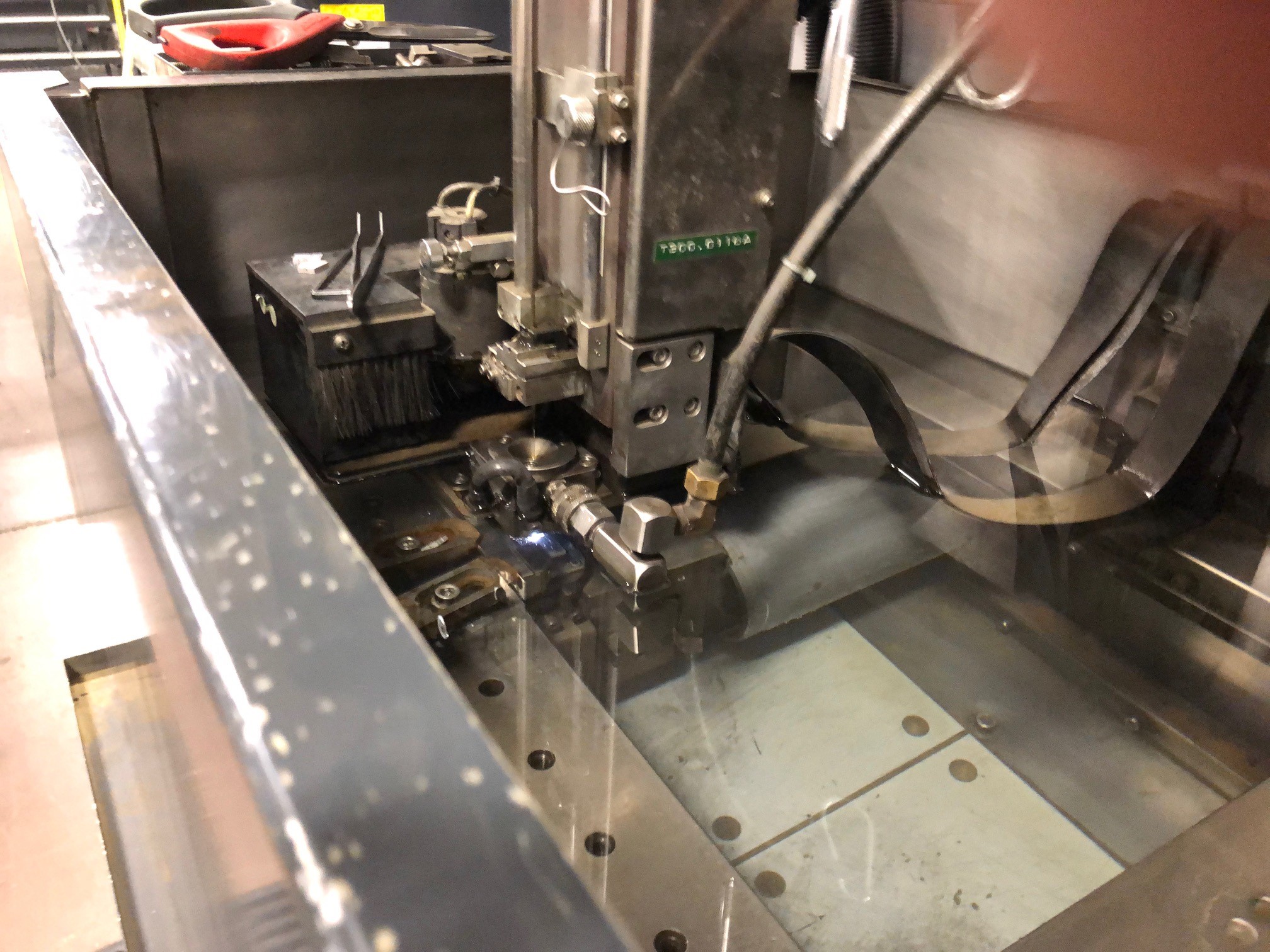

Wire EDM stands for Electric Discharge Machining. It is a metal manufacturing process that uses a strand of wire and electricity to erode a path through the metal to create the desired geometry and surface finish.

A wire is held on spools above and below the workpiece and moves sideways through the part. The workpiece is submerged in deionized water and is attached to a worktable. During the erosion process, the wire is spooled downwards so fresh wire is constantly fed towards the part.

In the wire EDM process, the wire never touches the part, but instead thousands of electrical sparks “chip” away at the material. This leaves a smooth surface finish and no stress is introduced into the part.

Types of Metals We Accommodate

EDM machines are used on conductive materials to create the electrical reaction needed for the process. At PEKO, we perform wire EDM services on many materials every day.

Some common materials are as follows:

- Copper

- Brass

- Aluminum

- Super Alloys

- Tool Steels

- Carbon Steels

- Titanium

- Tungsten

- Exotic Metals

Wire EDM Machining Applications

Wire EDM machining can come in many forms and applications. Here are some common applications:

- Small parts

- Intricate geometries

- Tooling

- Fixtures

- Curves

- 5-axis curves

- Tight tolerances

- Smooth Surface finishes

- Small features

PEKO’s wire EDM services provide customers with an option for very unique parts. As a secondary offering for PEKO, we use these machines for customers that have precision assemblies with very high tolerance components.

For the most up-to-date information on our EDM capabilities, please visit our Facilities Page.