Why Sheet Metal Hardware Matters

Sheet metal hardware is a cornerstone of modern manufacturing. From lightweight aerospace assemblies to robust automotive chassis and precision electronic housings, hardware selection and installation directly determine product safety, durability, and performance.

At its foundation, sheet metal is produced in thin, flat stock, measured in standardized gauges. A higher gauge corresponds to a thinner sheet. Engineers select gauge thickness according to load-bearing requirements, fabrication process (stamping, bending, welding), and final application environment.

Common Sheet Metals:

| Material | Properties | Typical Applications |

|---|---|---|

| Low-carbon steel | High strength, weldable | Automotive panels, construction |

| Aluminum alloys | Lightweight, corrosion resistant | Aerospace, enclosures |

| Copper & brass | High conductivity | Electrical components |

| Stainless steel | Corrosion & heat resistant | Medical, food-grade equipment |

These base materials dictate which hardware types and coatings are viable. For example, a galvanized steel fastener in aluminum can cause galvanic corrosion if not properly isolated.

Common Types of Sheet Metal Hardware

Fasteners: Screws, Bolts, Nuts, and Washers

Fasteners remain the primary method for joining sheet metal assemblies. Correct preload is critical: under-tightening risks loosening, while over-tightening risks thread stripping or bolt fracture.

Fastener Considerations:

- Thread form selection – Unified, metric, or specialty threads.

- Torque–tension relationship – Depends heavily on lubrication and friction.

- Washers – Distribute clamping force, prevent surface damage.

| Fastener Type | Advantages | Limitations | Common Uses |

|---|---|---|---|

| Machine screws | Easy assembly/disassembly | Requires tapped holes or nuts | Electronics enclosures |

| Bolts & nuts | High clamping strength | Space required for nut side | Structural frames |

| Self-tapping screws | No pre-tapped holes | Can damage thin sheets | HVAC, light-gauge panels |

| Lock washers / tooth washers | Resist loosening | Limited reuse | Automotive vibration-prone joints |

Rivets

Rivets provide permanent fastening, ideal for thin sheets subject to vibration (aerospace fuselages, transportation).

- Solid rivets – High shear strength; used in aircraft skins.

- Blind rivets – Allow installation from one side.

- Specialty rivets – Swell-neck, countersunk, and structural rivets.

| Rivet Type | Strength | Installation | Example Applications |

|---|---|---|---|

| Solid rivet | High | Requires both sides | Aircraft assembly |

| Blind rivet | Medium | One-side install | Enclosures, HVAC |

| Drive rivet | Low | Hammer set | Decorative panels |

Clips, Clamps & Brackets

Clips, Clamps & Brackets

- Clips and clamps – Provide quick fastening, common in prototype builds, HVAC ducts, cable routing.

- Brackets – Transfer structural loads and provide mounting points. Proper bracket design requires stress path analysis to avoid sheet deformation under cyclic loading.

Hinges

Hinges allow controlled pivoting movement. Selection must consider load per hinge, frequency of operation, and wear resistance.

| Hinge Type | Function | Application |

|---|---|---|

| Butt hinge | Simple pivot | Doors, cabinets |

| Continuous (piano) hinge | Load distributed along full length | Enclosures, aerospace panels |

| Pivot hinge | Allows offset rotation | Machinery, equipment housings |

Retaining Hardware: Pins & Rings

- Pins (dowel, taper, roll pins) provide precision alignment.

- Retaining rings secure axial position of components on shafts or inside housings.

These components are designed for serviceability, allowing repeated disassembly without loss of holding force.

Applications of Sheet Metal Hardware

Sheet metal hardware is found in nearly every industry. Its adaptability allows it to serve both structural and protective functions.

| Industry | Hardware Role | Example Applications |

|---|---|---|

| Automotive | Bolts, clips, brackets | Panel assemblies, engine mounts |

| Aerospace | Rivets, lightweight fasteners | Fuselage, wing structures |

| Construction | Hinges, clamps, sheet panels | Roofing, ductwork |

| Electronics | Screws, clips, enclosures | Server racks, EMI shielding |

| Medical | Stainless fasteners, hinges | Surgical instruments, housings |

| HVAC | Sheet joints, rivets, clamps | Ducting, louvers, ventilation units |

Selection Criteria for Sheet Metal Hardware

When selecting hardware, engineers must analyze:

- Mechanical Performance

- Tensile, shear, and fatigue strength of fasteners and rivets.

- Allowable load per hardware type from standard charts.

- Material Compatibility

- Use galvanic series to avoid corrosion.

- Apply coatings (zinc plating, anodizing) to improve durability.

- Assembly & Maintenance

- Blind rivets for inaccessible joints.

- Reusable fasteners for assemblies requiring disassembly.

- Cost vs. Lifecycle

- Low upfront cost fasteners may increase long-term maintenance costs.

- Environmental & Aesthetic Requirements

- Visible assemblies often require flush fasteners or decorative finishes.

Sheet Metal Hardware Installation Techniques

Best Practices

- Surface preparation: Clean, remove burrs, ensure flatness.

- Hole preparation: Drill to proper clearance size (see Machinery’s Handbook drill size tables).

- Torque application: Follow torque–tension curves to avoid over-stressing bolts.

- Use of washers: Prevent localized crushing of thin sheet.

- Sequential tightening: Tighten bolts in a cross-pattern for even load distribution.

- Rivet setting: Ensure correct shank length for full deformation.

Common Installation Failures

| Failure Mode | Cause | Prevention |

|---|---|---|

| Bolt loosening | Insufficient preload, vibration | Use lock washers, prevailing-torque nuts |

| Rivet pull-through | Thin sheet, oversized hole | Use backing washers |

| Cracking around holes | Poor edge distance | Maintain ≥ 2× hole diameter from edge |

| Galvanic corrosion | Dissimilar metals in contact | Use isolating washers, coatings |

Engineering Reliability in Sheet Metal Assemblies

Sheet metal hardware is not simply a collection of fasteners and brackets—it is the engineered interface between structural performance and manufacturability.

By:

- Selecting hardware with proper mechanical ratings,

- Ensuring material compatibility,

- Applying correct installation practices,

engineers can extend product life, reduce service failures, and achieve cost-effective, high-performance assemblies.

Takeaway: The reliability of sheet metal assemblies is only as strong as the hardware securing them.

Partner with PEKO’s Sheet Metal Experts

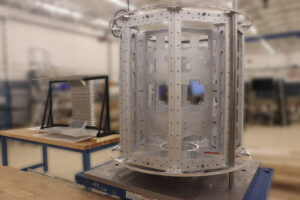

Choosing the right sheet metal hardware is only one part of achieving a reliable, high-performance assembly. The real advantage comes from pairing quality components with expert engineering and precision fabrication.

At PEKO, our sheet metal engineers bring decades of experience in design-for-manufacturability (DFM), hardware selection, and precision assembly practices. Whether you require aerospace-grade riveted structures or custom electronic enclosures, our team ensures your project benefits from optimal hardware choices, material compatibility, and efficient installation methods.

Contact our sheet metal fabrication experts today and let us help engineer a solution that balances strength, cost, and manufacturability for your application.