When it comes to sheet metal fabrication, choosing the right mechanical fastening methods can make or break the performance, durability, and serviceability of your design. Whether the goal is permanent assembly, quick disassembly, or structural integrity under high stress, the fastening method must align with function, material thickness, and production efficiency.

Below, we break down the four major categories of fastening in sheet metal fabrication—threaded, non-threaded, integral, and welded joints—along with their advantages, disadvantages, and best-use cases.

1. Threaded Fastening

Threaded fasteners are the workhorse of sheet metal assemblies—ideal for applications that require disassembly and reassembly during maintenance or product upgrades. Common threaded options include:

- Loose Hardware: screws, nuts, bolts, studs, tapping screws

- Self-Clinching Fasteners: such as PEM® nuts, which are pressed into sheet metal and become a permanent part of the panel

Advantages:

- High reusability

- Strong joint integrity in thin sheet stock

- Simplifies serviceability and replacement

Disadvantages:

- Requires tapped holes or pre-installed clinch hardware

- More parts inventory (nuts, bolts, washers, etc.)

Comparison: Loose vs. Self-Clinching Fasteners

| Feature | Loose Hardware | Self-Clinching Fasteners |

|---|---|---|

| Reusability | High | Moderate (permanent insert, reusable screw) |

| Ideal Thickness | Medium to thick panels | Thin sheet (<0.040 in.) |

| Installation Speed | Manual or automated | Press-in (high speed) |

| Strength in Thin Sheets | Poor | Excellent |

2. Non-Threaded Fastening

When simplicity and speed are priorities, non-threaded fastening offers durable, cost-effective solutions. These include:

- Pins & Dowel Pins – used for locating, pivoting, or locking

- Washers – distribute loads, reduce vibration, and prevent galling

- Rivets – provide permanent fastening comparable to welding, excellent for shear strength

- Adhesives – bond dissimilar metals, seal against corrosion, and reduce stress concentrations

Advantages:

- Quick installation

- No tapped holes required

- Can bond or join dissimilar materials

Disadvantages:

- Limited reusability

- Some methods (adhesives) require surface prep and curing time

Strength Comparison: Riveting vs. Adhesive Bonding

| Property | Rivets | Adhesives |

|---|---|---|

| Joint Permanence | Permanent | Permanent |

| Shear Strength | High | Moderate |

| Vibration Resistance | Excellent | Good |

| Corrosion Protection | None (requires coating) | Excellent (sealing effect) |

3. Integral Mechanical Attachment

This method forms the fastening feature directly into the sheet metal during fabrication—no external hardware required.

- Clinching – embossing protrusions to interlock two sheets

- Hemming & Seaming – folding edges for reinforcement or joining panels

- Tab & Slot Assemblies – bent tabs fitted into slots for structural alignment

- Snap Fits – hooks or studs deflect and lock into place

Advantages:

- Eliminates hardware costs

- Reduces assembly complexity

- Enables high-speed, automated production

Disadvantages:

- Limited strength compared to welding

- Not ideal for repeated disassembly

Where Integral Fasteners Excel

| Method | Best Use Case |

|---|---|

| Clinching | Joining dissimilar metals quickly |

| Hemming | Reinforcing edges, aesthetics, safety |

| Seaming | Air/water-tight joints in HVAC or enclosures |

| Snap Fits | Consumer electronics, quick assembly |

4. Thermal Joining & Welding

For the highest structural integrity, welding fuses sheet metal parts into a single, permanent component. Common methods include:

- MIG & TIG Welding – versatile for thin-gauge sheet metal

- Resistance/Spot Welding – fast, cost-efficient for high-volume assemblies

- Brazing & Soldering – joining dissimilar metals at lower heat input

Advantages:

- Permanent, high-strength bonds

- Excellent for structural and load-bearing assemblies

Disadvantages:

- Not reversible

- Requires skilled labor or automation

- Heat distortion possible in thin sheet

Comparison: Riveting vs Welding

| Property | Riveting | Welding |

|---|---|---|

| Joint Strength | High (shear-focused) | Very High |

| Speed (per joint) | Fast (pneumatic) | Moderate |

| Disassembly | Not possible | Not possible |

| Distortion Risk | Low | High (thin sheet) |

→ Want a deeper breakdown of these two fastening methods? Check out our detailed article on Riveting vs Welding (coming soon).

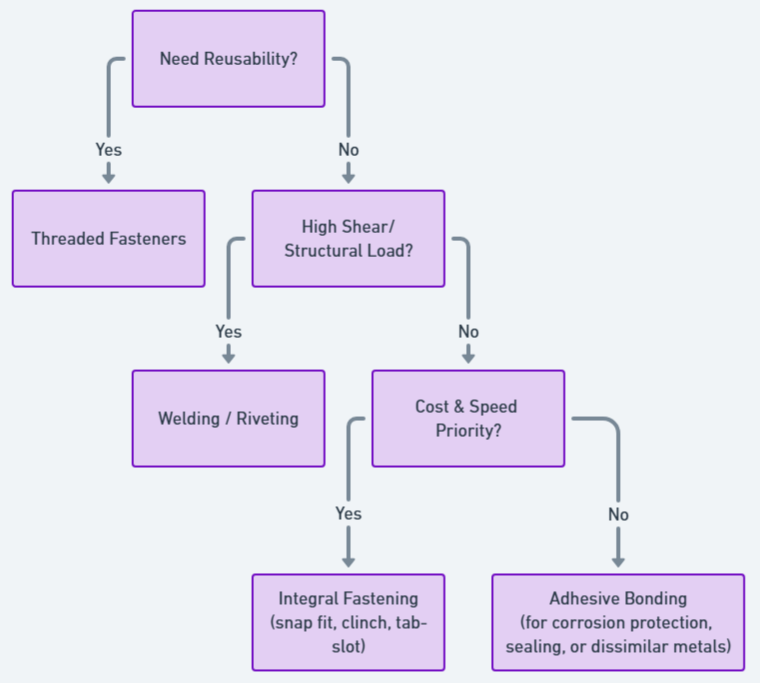

Choosing the Right Mechanical Fastening Method for Your Application

The correct fastening method depends on application requirements, production volume, and serviceability needs.

Mechanical Fastening Methods Selection Flowchart

Mechanical fastening methods in sheet metal fabrication offer a spectrum of performance trade-offs—balancing cost, strength, serviceability, and production efficiency.

At PEKO, our engineering teams leverage all fastening approaches—threaded, non-threaded, integral, and welded—to meet the precise demands of OEM customers across industries. Whether the goal is quick disassembly for service, permanent high-strength joints, or optimized DFMA (Design for Manufacturing and Assembly), we tailor fastening methods to ensure reliable, cost-effective assemblies.

Contact us today to speak with our engineering team and discover how we can support your design, fabrication, and assembly needs.