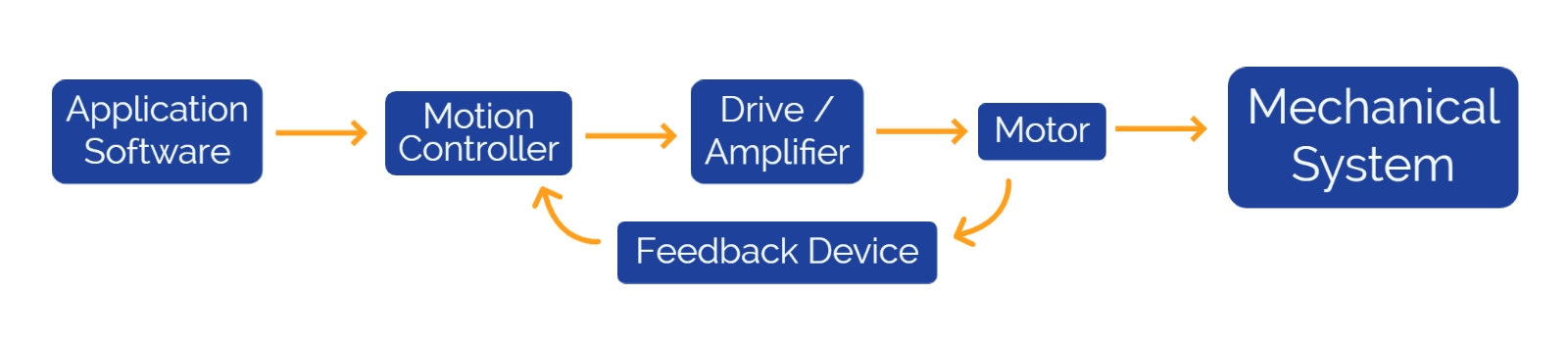

When it comes to motion control systems, there are a few key components that are essential for the system to work properly: a motion controller, a motor driver or amplifier, a motor, and a feedback device. Without these components, the system would not be able to function.

In this blog post, we will discuss these key components of a motion control system and what each one does.

Note: Often, there is overlap between the software, controller, and amplifier. Sometimes these could all be in one drive, or three separate components, as shown.

Motion Control System Components

1. Motion Controllers

The first key component of a motion control system is the controller. The controller is responsible for sending commands to the motor drive(s), which then causes the desired motion to occur.

A motion controller could be a PLC sending commands directly to a drive or specialized hardware for just motion control. The motion controller would take instructions from the software combined with feedback from the motor and other sources (sensors, etc.) to make a decision.

It is important to note that not all controllers are created equal. Some controllers are more powerful than others. They can contain one or more motor drives, be capable of complex (multi-axis) motion, and have a variety of I/O capabilities.

If you have a large or complex motion control system, it is important to choose a controller that can handle the amount of work that needs to be done.

2. Motor Drives (Amplifiers)

Another key component of a motion control system is the drive/amplifier. The drive/amplifier converts the low energy signals from the controller into high energy signals used to drive the motor (the next key component).

These components come in a variety of input/output power configurations and must be matched to the type of motor being used in the application.

Some popular features include system closed-loop motion, pre-programmed motion profiles, and feedback to the controller. In some cases, more features are integrated into these amplifiers.

In some cases, these are built into motion controllers for a complete solution in one package, as is the case for a servo drive.

3. Motors

The next key component of a motion control system is the motor. The motor is responsible for converting electrical energy into mechanical energy, which then causes the desired motion to occur.

There are many different types of motors available on the market, so it is important to select one that is best suited for your application.

Some common types are servo, stepper, AC or DC-brush, and brushless. Common selection criteria are things like maintenance, speed, torque, feedback, cleanliness, and smoothness.

If you are not sure which type of motor to choose, consult with an expert like PEKO who can help you make the right decision.

4. Feedback Sensors

Finally, feedback sensors are an important component in motion control systems. Based on system requirements, knowing the position, velocity, or torque of the motor may be needed.

Feedback sensors, such as encoders, are used to give information about the position and direction information about the servomotor.

Encoders are the most common tool used to determine the position and velocity of a motor and are required for a true closed-loop system.

The topic of feedback includes sensors, potentiometers, encoders, interferometers, and more which will be best suited for another blog.

Issues with Motion Control System Components

Now that we have discussed the key components of a motion control system, let’s look at some common problems that can occur with these components.

- One frequent problem that can occur with the controller is communication errors. If the controller cannot communicate with the amplifiers or motors, then the system will not be able to function properly. To address this issue, ensure a robust connection between the controller and the drive. This could be digital, analog, or using a communication protocol such as Ethernet/IP or Modbus.

- Another frequent problem that can occur is amplifier issues. If the amplifier is unable to provide enough current or voltage for the components, then they may not work correctly. The drive/amplifier must be sized properly for the motor and load in the system. A drive that is not properly sized may be damaged during use or not capable of controlling the motor reliably.

- Finally, one of the most common problems that can occur with the motor is mechanical failure. If the motor fails, then the desired motion will not occur.

By understanding these key motion control system components and what can go wrong with them, you will be better equipped to troubleshoot any issues that may arise with your motion control system.

Stay tuned for future blog posts where we will have a more in-depth discussion about each of these motion control components. If you are unsure which products are necessary for your application, we can help you determine what you need. Submit your project details to start working with a motion control expert at PEKO today!

Share article: