Are you a startup or an OEM bringing a new medical device to the market? Are you unsure of how you will tackle the commercialization process? Do you have stakeholders and investors on edge pestering when your final product will hit the market? If yes, then you’ll likely benefit from outsourcing your medical equipment to a contract manufacturer.

When a company is trying to bring a medical device to market, there’s a lot at stake because the industry requires additional tests and processes during manufacturing. A few months ago, we wrote a blog on the extra elements required for medical device development. In this post, we’ll highlight some of the benefits companies can expect when outsourcing medical equipment to an experienced contract manufacturer.

Continuous Cost-Down Opportunities

Cost-down opportunities aren’t just limited to the beginning of a product’s life cycle. In fact, a successful contract manufacturer should be considering cost-down opportunities whenever possible. At PEKO, we always look toward the long-term goals of our customers. By doing so, we can assist our customers in reducing costs so they can continue to improve their technology.

Recently, PEKO managed to save one of our medical device OEM customers about $5,000 per unit. With the due diligence from a dedicated program manager, coupled with our inclusive engineering staff, PEKO was able to remove extra component pieces from each unit and redesign the component parts. Since some of the extra component pieces were not serving the purpose which they were intended, we were able to remove the unnecessary parts completely and redesign others.

Reliable Supply Chains

No matter how perfect a company’s design is, or how knowledgeable a contract manufacturer may be, problems can still arise once a product has reached the market. Out-of-service equipment can have frustrating impacts for any industry, but these frustrations can become ten-fold when used in the medical industry.

Rather than dealing with the cumbersome act of sending entire units back, a contract manufacturer can assist medical device companies in creating repair kits. If a company had chosen to outsource medical equipment manufacturing to multiple different locations and companies, it would be hard to resolve malfunctioning issues in a quick, timely manner.

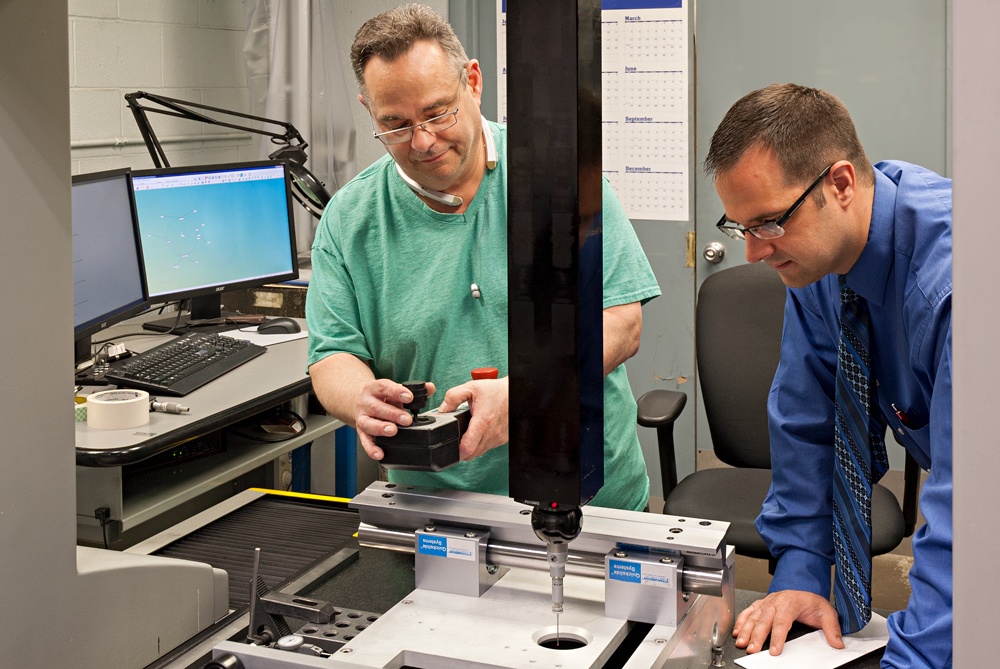

NPI Engineering Support

An NPI group is essential when working out any concerns in a product’s design. A contract manufacturer’s NPI team will have plenty of background in medical industry requirements and can effectively review and assess a design’s manufacturability. Successful NPI Engineers will work through your design’s drawings while holding weekly calls with you to ensure that each component part and assembly will be completed to the best of their ability once manufacturing takes place. When OEMs outsource medical equipment to a contract manufacturer like PEKO prior to the product’s launch, they can rely heavily on our experienced New Product Introduction Engineers.

When Medical Device Companies enter a contract with a successful and experienced Contract Manufacturer, the two companies can cohesively use their competencies to successfully bring new technology to market.

Through cost-down opportunities, the Medical OEM can reinvest their money into their next big idea and have the peace of mind of knowing only one company is managing their product’s manufacturing. An added benefit is finding a contract manufacturer that has a dedicated NPI Engineering department that can assist with refining and optimizing your design prior to scaled manufacturing.

Through cost-down opportunities, the Medical OEM can reinvest their money into their next big idea and have the peace of mind of knowing only one company is managing their product’s manufacturing. An added benefit is finding a contract manufacturer that has a dedicated NPI Engineering department that can assist with refining and optimizing your design prior to scaled manufacturing.

Share article: