In sheet metal manufacturing, tool and die design is crucial for producing high-quality parts with efficiency and precision. Whether you’re working with simple blanks or complex formed parts, understanding the fundamentals of die design is essential for achieving the desired results. The right tools and dies can reduce waste, extend tool life, and improve production speed.

This blog explores the key principles of tool and die design in sheet metal operations—covering cutting, forming, and shaping processes—to equip you with the knowledge necessary to make informed decisions about tool design to maximize performance.

What Is Tool and Die Design?

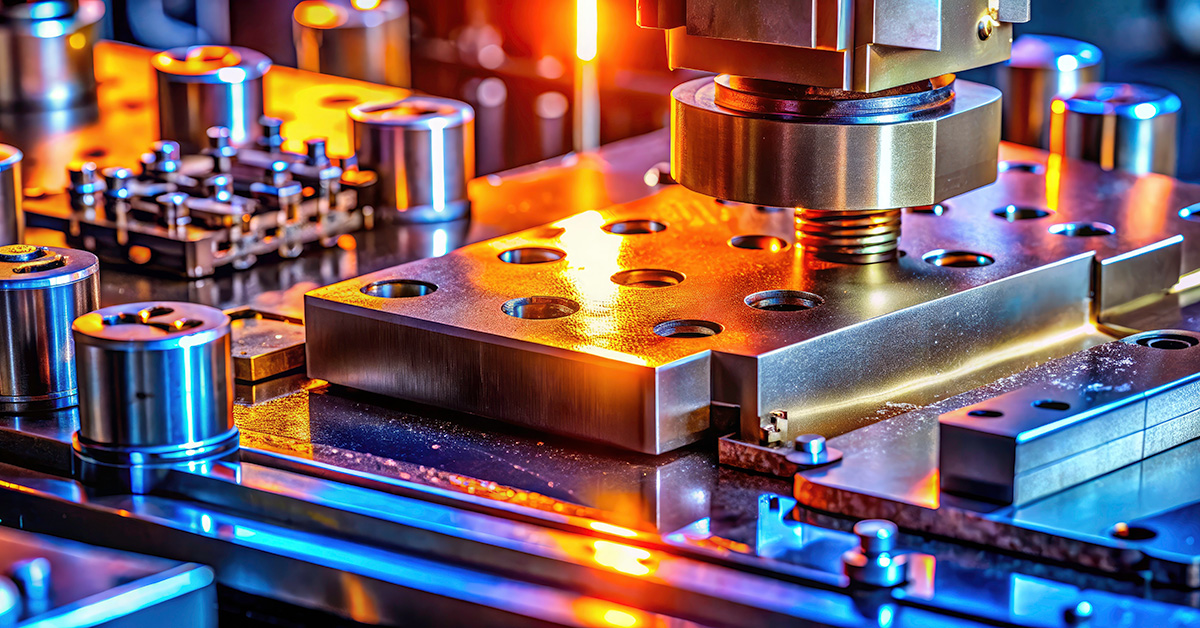

Sheet metal tooling refers to the mechanical devices utilized for cutting, shaping, supporting, or molding metals. Sheet metal dies are a particular type of tool that serve to change the shape of the metal in a functional manner. In operations like stamping, punching, bending, and drawing, the tools and dies provide the essential force needed to shape the metal into its finished product.

Effective tool and die design are crucial for producing parts that meet specifications, while also ensuring accuracy, reducing tool wear, and improving the efficiency of the entire process.

Key Considerations for Tool and Die Design

Sheet metal tooling and die design requires a deep understanding of both the material properties and the mechanical processes involved. Key considerations include:

1. Material Selection for Dies

The material chosen for the die must withstand the stresses of repeated use. Tool steels, such as high-carbon steels (A2, D2) or alloy steels, are commonly used for dies due to their hardness and wear resistance. Material hardness is directly linked to tool performance—harder materials can withstand greater stress, making them more suitable for high-volume applications where tool wear is a concern.

2. Die Types: Single-Operation vs. Progressive

There are two main types of dies used in sheet metal operations: single operation dies and progressive dies.

- Single operation dies: Used for a single operation (e.g., cutting, punching), these dies perform one task per stroke. They are simpler but are limited to parts that require only one operation.

- Progressive dies: These dies perform multiple operations in a sequence, allowing a single stroke to complete several tasks, such as punching, bending, and blanking. Designing progressive dies is a complex process, requiring careful alignment and sequential tooling to ensure each operation is performed correctly.

3. Die Clearance and Tolerances

Clearance refers to the space between the punch and die, which must be designed carefully to ensure clean cuts and minimal wear. The correct clearance depends on the material type and thickness. In punching operations, the following clearance guidelines are recommended to avoid excessive deformation or tool damage:

| Material | Clearance (Punch-to-Die) |

|---|---|

| Mild Steel | 5-10% of material thickness |

| Aluminum | 7-12% of material thickness |

| Stainless Steel | 5-7% of material thickness |

| Copper | 5-10% of material thickness |

4. Cutting and Punching Dies

In cutting operations such as shearing and punching, the punch applies force to the sheet metal to separate it. The design of these cutting dies is essential for achieving smooth, accurate cuts. The force required for punching or shearing is based on the shear strength of the material, the stock thickness, and the length of the cut. For a circular hole, the punching force in tons is given by:

F = πDTS / 2000

Where:

= punching force (tons)

= hole diameter (in.)

= stock thickness (in.)

= shear strength of the material (lb/in²)

2000 = conversion from pounds to tons

For non-circular holes, replace DD with one-third of the perimeter of the hole.

Approximate Formula for Steel:

F ≈ D × T × 80

with D in inches, T in inches, result in tons.

5. Bending Dies and Forming

In bending operations, dies with a “V” shape, known as V-dies, are commonly used. When the sheet metal is inserted into the V-die, a punch presses the material to create the bend. To ensure a clean, precise bend, engineers need to account for springback—the tendency of the material to return to its original shape after being bent. The following formula can be used for calculating bend allowance (BA), which accounts for the elongation of sheet metal along the neutral axis during bending:

BA = θ (R + K × T)

Where:

= bend allowance (in. or mm)

θ = bend angle (radians)

= inside bend radius (in. or mm)

= material thickness (in. or mm)

= K-factor (ratio locating the neutral axis, typically 0.3–0.5 depending on material and process)

6. Die Maintenance and Wear

Sheet metal tooling and die longevity are essential to maintaining production efficiency. Regular maintenance practices, such as cleaning and lubrication, can significantly extend the life of tools and dies. Additionally, interchangeable inserts in dies can reduce the impact of wear, allowing the die to be replaced or reconditioned without replacing the entire tool.

Example: Progressive Die Design for Stamping

For a progressive die used in stamping, multiple operations are performed in a single cycle. Consider a die designed to punch holes, bend edges, and form a complex part in a single stroke.

In this case, the material progresses through several stages within the die, and each station performs a different operation. To ensure the accuracy and efficiency of this process, engineers must consider factors such as proper alignment of the punches and die cavities, the material’s strain hardening characteristics, and the feed system to ensure smooth material movement.

Effective tool and die design are essential for the success of any sheet metal operation. By adhering to these principles—such as proper material selection, clearance calculation, and bend allowance—engineers can optimize die performance, reduce tool wear, and ensure precise, high-quality parts.

For expert assistance with sheet metal tooling and die design, look no further than PEKO. Whether you’re designing a simple cutting die or a complex progressive die, our expertise in precision sheet metal fabrication will guide you through these challenges, ensuring operational efficiency and cost-effective production. Submit your project details to our experts today.