One of the most exciting parts of working in the machinery industry is staying on top of the latest innovations. Every day my inbox is full of news on how new technologies are being implemented in machinery and production systems across industries.

Sure, some of these are sponsored posts or paid content—but that doesn’t make them any less interesting. Watching peers in the machinery space push the boundaries of manufacturing and share real-world results is both informative and inspiring.

The machinery industry can be a tough road, and striking the balance between proprietary know-how and publicly shared insights creates a powerful forum for innovation. News feeds, webinars, videos, and technical papers all serve as excellent venues for showcasing the newest machinery industry trends.

Here are a few of the most notable ones I’ve been following this year.

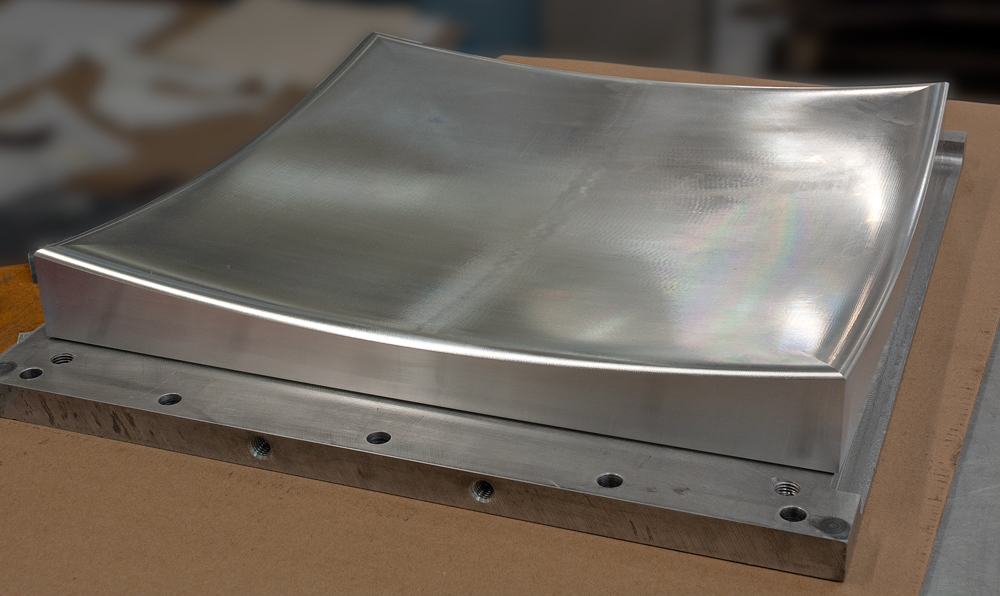

1. Additive Manufacturing

Additive manufacturing has transformed the machinery industry over the past decade. 3D printing is no longer just for prototypes—it’s influencing how OEMs and contract manufacturers alike approach design, cost-benefit analysis, and production scaling.

Key impacts include:

- New ways to design and iterate complex parts

- Expansion of printable materials and component geometries

- Fresh approaches to cost justification versus casting, machining, and molding

- Shifts in cycle time, tolerance expectations, and post-processing methods

Historically, additive has been limited in high-volume production due to long build times. However, companies like Cummins are now using binder jet technology for production-grade engine components, demonstrating that additive manufacturing is entering the mainstream of machinery industry trends.

In an Industry Week article, we learn that about how they are using binder jets for a critical engine emissions component.

“The part, now moving through Cummins’ production part approval process (PPAP) for formal approval, is a Cummins Emission Solutions (CES) lance tip adapter used in high horsepower engines.”

With the likely success of this part run, Cummins will enjoy the benefits of lower costs, increased speeds, improved functional geometry, and elimination of complex manufacturing operations. At PEKO, our engineers have worked closely with leading 3D printing OEMs to develop equipment for these applications, seeing firsthand how additive is reshaping machinery design and production.

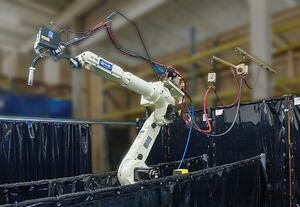

2. Robotics

Robotics remain one of the most influential machinery industry trends. Collaborative robots (cobots), autonomous systems, and advanced inspection tools are making robotics more flexible and accessible than ever.

Traditionally, robots were associated with high-speed automotive lines. Today, new use cases are rapidly emerging across industries:

- Portable inspection and measurement systems

- Automated material handling equipment

- Robotics for aerospace, defense, and space applications

- Security and field-deployable robotic platforms

Regions like Pittsburgh are becoming recognized hubs for robotics innovation, complementing long-standing centers like Silicon Valley and Boston. At PEKO, we’re actively supporting OEMs developing automated material handling systems—one of the fastest-growing robotics applications in the machinery industry.

3. 3D Virtual Tours

In a B2B machinery industry where in-person factory visits were once essential, digital tools are redefining how buyers evaluate suppliers.

Traditionally, OEMs considering a new manufacturing partner would visit a facility to assess cleanliness, layout, and scale. Travel slowdowns during the pandemic accelerated demand for virtual alternatives.

3D virtual factory tours now allow prospects to explore an entire facility online, with navigation similar to Google Street View but with much higher definition. These immersive experiences highlight machinery, equipment layout, and production capacity, providing confidence and credibility before formal engagement.

While cost and security concerns must be managed, the benefits—greater visibility, improved supplier trust, and easier early-stage evaluation—make 3D virtual tours a standout trend in the machinery industry. Matterport is an up-and-coming host for this service and has local agents across the country.

Machinery industry trends span everything from capital equipment innovations to new digital engagement tools. What’s most exciting is the industry’s willingness to adopt new technologies—from additive and robotics to digital communication platforms—at a pace that would have been unthinkable even a decade ago.

Machinery industry trends span everything from capital equipment innovations to new digital engagement tools. What’s most exciting is the industry’s willingness to adopt new technologies—from additive and robotics to digital communication platforms—at a pace that would have been unthinkable even a decade ago.

For OEMs navigating this evolving landscape, the right contract manufacturing partner can help translate these trends into competitive advantages. Download our guide to outsourcing to a contract manufacturer to help determine the best fit for your next project.