The Assembly Show 2025 in Chicago packed more than 600 exhibitors and a few thousand conversations into three intense days. We didn’t exhibit; we listened. Our aim was simple: collect practical ideas OEM machine builders can apply to complex, low-volume, high-mix assemblies—ideas that improve quality, shorten lead times, and strengthen the digital thread. Below are the takeaways from the show we’re carrying back to the floor in Rochester.

Leak Testing Is Moving From “Find A Bubble” To “Prove A Seal”

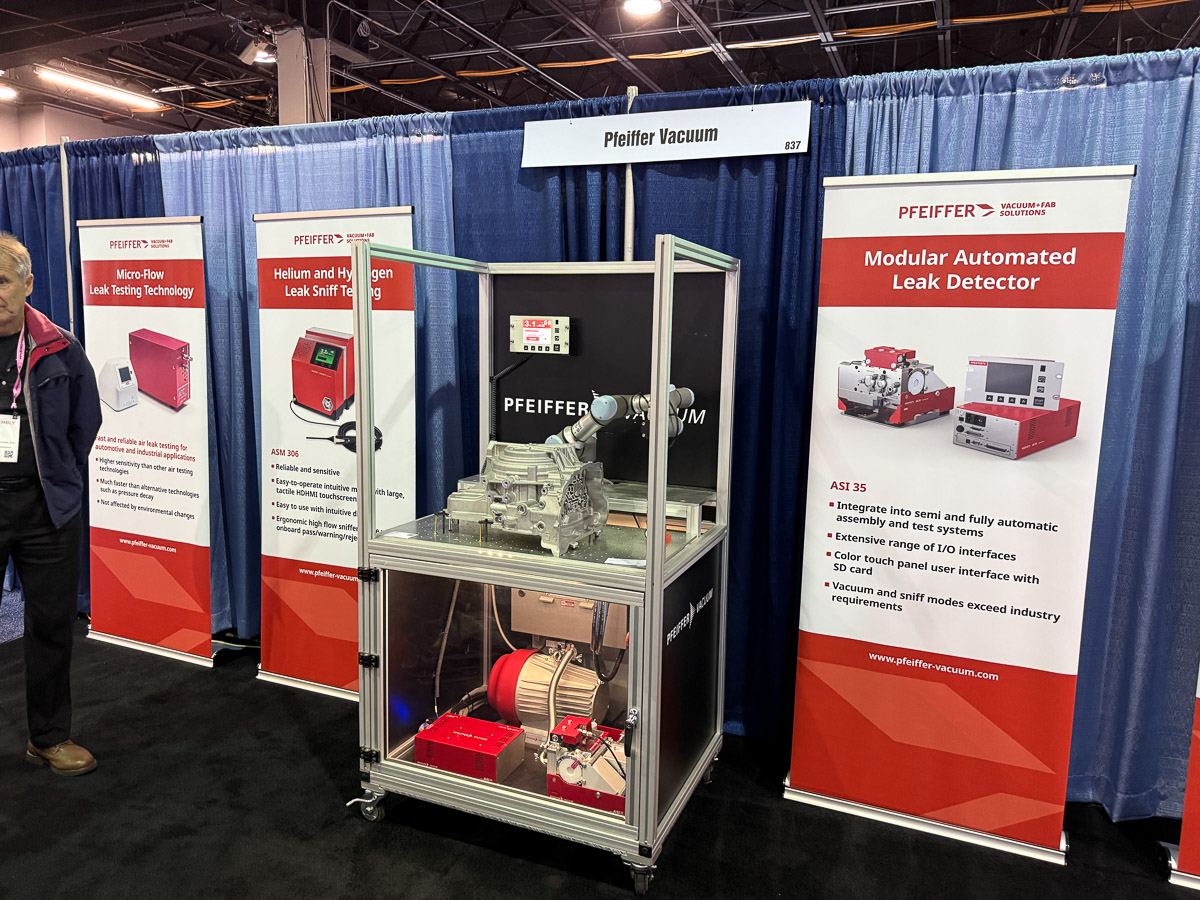

At Pfeiffer Vacuum’s booth, we watched a robotic sniffer identify a calibrated leak in seconds—precisely the kind of defect that might take half an hour to reveal itself in a water bath. The win isn’t just speed; it’s non-destructive sensitivity with inert helium that pinpoints location for rework and logs the event for traceability.

Across the aisle of ideas, Cincinnati Test Systems (CTS) positioned its Sentinel iX5 as a production-line workhorse, combining pressure-decay, differential, and mass-flow methods with a sequencing touchscreen. It’s the difference between high-sensitivity troubleshooting and high-throughput validation—and it’s a reminder to replace “no leaks” with quantifiable test thresholds tied to part function.

Lessons learned: Map each assembly to the right method: CTS-style pressure or mass-flow for inline production checks; helium sniffing for precision cooling plates or sealed housings that demand rapid localization. Build the data path now so these tests write directly into your traveler/MES records.

Right-Sized Robotics Beat One-Size-Fits-All Cobots

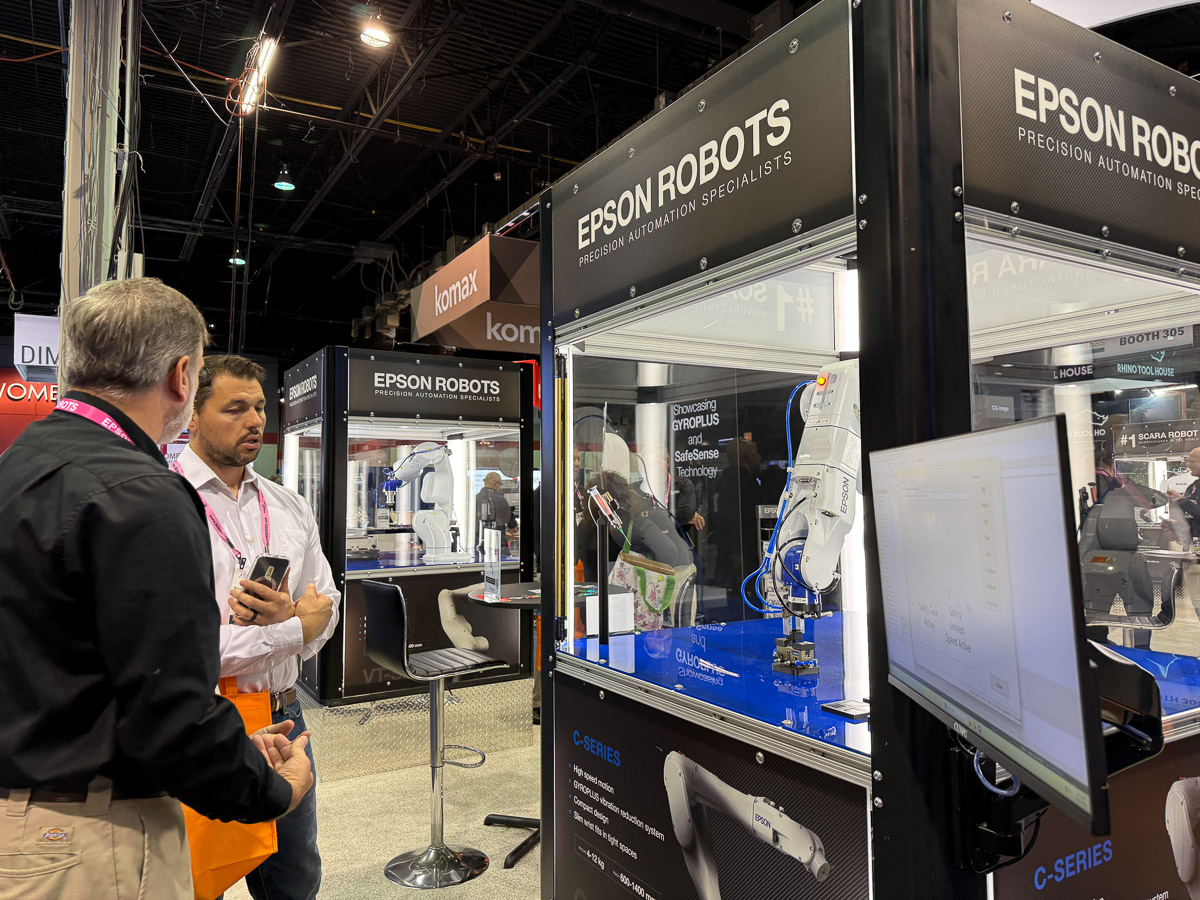

We’ve trialed CNC machine-tending cells. You probably have, too. The hard part isn’t the robot; it’s the math. On the floor at The Assembly Show 2025, Epson Robots put numbers to it: simple load/unload routines can take 4–8 hours to program, depending on experience. For short-run batches, setup can eclipse the savings. Their take: “industrial collaboration” (full-speed robots with safety scanners/SLS to slow down when humans approach) often outperforms slower cobots—provided the cell is dedicated to a product family long enough to amortize setup.

Lessons learned: Tag candidate parts by takt, variation, and fixture stability. If you can dedicate a machine for months—not days—robotic tending is likely ROI-positive. Otherwise, pursue poka-yoke fixturing, quick-change tooling, and semi-automation before full cells.

Fastening Is Finally Closing the Audit Loop

Auditors love the question: How do you know it was torqued? At The Assembly Show 2025, Torque Tech’s answer was concrete: tools that store up to 100,000 rundowns, mark each tighten as OK/NOK, and signal “batch complete” to a PLC only after every fastener passes. Data can travel via USB, SD, or Wi-Fi to a controller that talks open protocol. The goal isn’t a fancier wrench; it’s a digital receipt for every critical joint.

On the press-fit side, MC Fastening Solutions showed a servo press mounted in a center-balanced T-frame. That geometry keeps payload centered so integrators can downsize the handling robot and simplify the cell. Modular throats let you re-use the press as models evolve—useful in low-volume program shifts.

Lessons learned: Prioritize traceable torque on defense/aero builds and any assembly with high cost of failure. For press fits, consider center-balanced frames when robot payload margins are tight.

Digital Work Instructions Are Becoming the Backbone of Traceability

Two platforms pointed at the same problem we—and many OEMs—still have: PowerPoint and paper travelers. VKS emphasized speed to value: upload legacy docs as attachments, enforce “latest version only,” capture cycle time per step, and roll up status by work order without rebuilding everything from scratch. That alone reduces tribal knowledge and onboarding waste.

PICO took it a layer deeper: integrate torque tools, scanners, printers, ERP, PLM, and QMS so each step logs operator, workstation, tool serial, and pass/fail. Crucially for defense programs, they support on-prem deployments when cloud isn’t an option—an on-the-ground theme we heard repeatedly at The Assembly Show 2025.

Lessons learned: Pick one pilot product. Move its traveler into a digital instruction set with version control and step-time capture. In phase two, integrate one smart tool (torque or vision) to auto-log results to the same record.

AI Is Getting Practical—On Cameras & in Your ERP

Deltia’s proposition is deceptively simple: overhead cameras translate motion into time, turning “I think this takes an hour” into true cycle, walk, and dwell times. They claimed average ~25% productivity improvements through better line balance and material flow; and while they typically cloud-host analytics, they’ll go on-prem for defense at higher cost.

Rhino Toolhouse attacked the other bottleneck: finding root cause across siloed MES/ERP/SCADA when there’s a warranty issue. Their AI copilot can live on-prem behind your firewall (SOC 2/ISO posture noted) and pull a serialized build’s history into one answer instead of weeks of email archaeology.

Lessons learned: If you can’t see where time goes, start with cameras. If you can’t answer “what happened on this serial number?” in minutes, pilot an AI layer that can interrogate your existing systems—ideally in an on-prem configuration for regulated programs.

Quick Wins Still Matter: Wire Marking Is a Sleeper Lever

Small steps add up. At The Assembly Show 2025, Max USA Corp demoed a no-heat slip-on wire sleeve system that reduces a single label step from about 40 seconds (heat-shrink) to roughly 3 seconds, with sleeves costing a few cents and a modest printer investment. Their square sleeve prevents label spin; color schemes support standards (e.g., yellow for HV in some regions). For panels with hundreds of wires, hours per unit are on the table.

Lessons learned: Time your current labeling steps. If you’re heat-shrinking, pilot a no-heat sleeve on one panel family and bank the savings.

What This Means for OEM Machine Builders

- Treat tests as data sources. Leak and torque events should write to the traveler automatically, not live in a logbook.

- Automate where the math works. Use the 4–8 hour programming baseline to set minimum batch sizes for machine tending.

- Modernize travelers first, integrate tools second. VKS/PICO show two viable on-ramps, including defense-friendly on-prem.

- Don’t ignore low-drama wins. Wire labels and balanced press frames quietly unlock big throughput.

- Use AI where it reduces search time. Cameras for time studies; copilots for serialized root cause.

Final Take on The Assembly Show 2025

Trade shows often overflow with demos that feel far from home. This year felt different. Walking the floor at The Assembly Show 2025, we saw practical upgrades we can implement in days or weeks, not quarters: better tests, smarter fastening, clearer instructions, right-sized automation, and AI that answers real questions. For complex assemblies, that’s how you win—one provable step at a time.